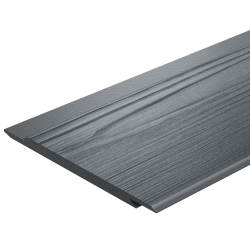

12mm Hardiebacker 500 Cement Wall Board

- Product Code: A1-1161

- Delivery Time: 2 - 4 days

- Brand: James Hardie

- Model and Size: 1200mm x 800mm - 0.96m2

- Weight: 13.80kg

4.6 out of 5 - Excellent

12mm Hardiebacker 500 Cement Wall Board

12mm Hardiebacker 500 is a cement wall board used as an ideal substrate for tiles and stone, made from cement, cellulose, sand and selected additives, containing no asbestos, formaldehyde or gypsum, which can disintegrate when exposed to high levels of moisture, which makes it a perfect choice especially in wet areas such as bathrooms or kitchens. The Mouldblock technology makies it not only moisture but also mould resistant, as it has no paper facing that could sustain mould growth. The board presents a perfect substitution for plywood or plasterboard, since it will not warp or rot when exposed to water, but provides substantial support, being able to withstand imposed loads of up to 100kg/m2.

12mm Hardiebacker 500 cement wall backerboard has very wide application as a wall backboard (including masonry walls) suitable for tile and stone in both commercial and residential applications, including areas with high levels of humidity, such as saunas, steam rooms, swimming pools or domestic boilers backing.

- Highly water and mould resistant,

- Durable, flexible and cost-effective,

- Easy to handle and install,

- High comprehensive and flexural strength;

- Free of asbestos, gypsum, glass fibre or formaldehyde.

Stud centres should be at the maximum of 400mm, all edges blocked with adequate timber and all existing dry lining removed. You may install the boards either horizontally or vertically, but make sure that all vertical joints are on the stud centre. Snap and cut the boards in accordance with the instruction given above. When using timber studs, adequate screws or roofing nails should be used for fixing the board. All wall and floor joints should be filled with proper wet area sealant and the boards installed at least 6mm from the floor, shower tray or bath. The fixings should be 15mm from the board edges and 50mm from the board corners, whereas all fixing heads should be set flush with the surface. A 50mm alkaline resistant Fibatape should be embed across the joints prior to applying the tiles. Please refer to the applicable regulations on whether a vapour control layer is necessary.

When installing the boards onto masonry walls, make sure that the wall surface is dry and clean and the board surface has no settled dust. The back of the board should be covered with high strength cartridge adhesive and pressed firmly onto the wall. The boards are further fastened with stainless steel screws, placed 100mm from the bottom and top edges and 50mm from the right and left ones.

- Evaluated by the BBA and approved with certificate no. 04/4100;

- In accordance with EN 12467;

- Classified as fully non-combustible, in accordance with the EN 13501-1, is A1,S1-d0.

HardieBacker Cement Backerboard Brochure

HardieBacker Cement Backerboard Brochure