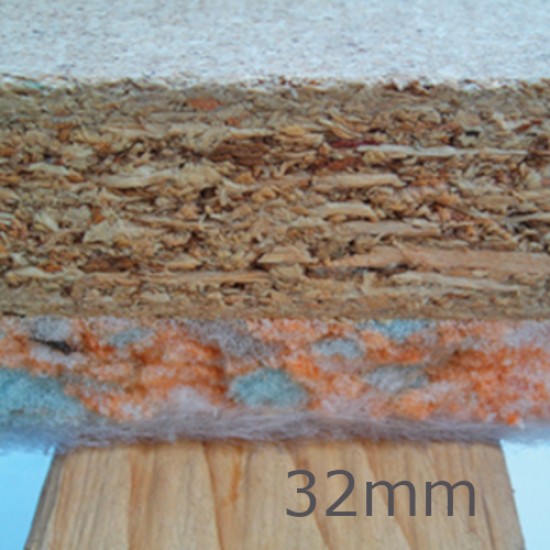

32mm Isocheck 32T Floor Insulation Board

- Product Code: A1-1036

- Delivery Time: 3 - 5 days

- Brand: Isomass (Tech. support: 08458383389)

- Model and Size: 600x2400mm - 1.44m2

- Weight: 23.00kg

4.6 out of 5 - Excellent

32mm Isocheck 32T Floor Insulation Board

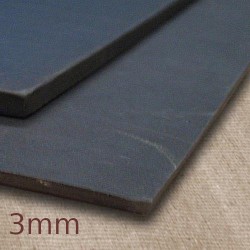

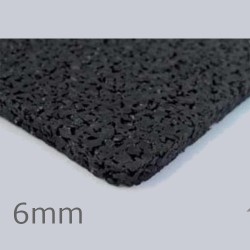

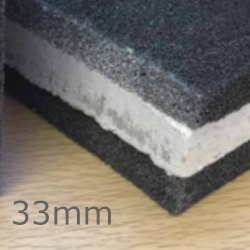

Isocheck 32T is an direct to joists floor system, designed for reducing sound transmission and improving acoustic and thermal performance of traditional timber joisted floors. The system is used in new build, refurbishment and conversion applications (especially if new resilient bar ceiling is installed), able to meet the requirements of the Building Regulations, Approved Document E 2003 (including the subsequent amendments in 2004 and 2010). The system includes 22mm P5 V313 chipboard bonded to acoustic chip foam and 4mm Isofiba core, 6mm thick.

- High acoustic and thermal properties;

- Able to meet values prescribed by the Approved Document E of the Building Regulations, when installed as part of a complete sound reduction system;

- Consisting of a moisture resistant chipboard and acoustic chip foam for improving acoustic insulation.

Isocheck 32T Floor Insulation Board is applicable in new build, refurbishment and conversion applications, installed over traditional timber joisted floors, especially if new resilient bar ceiling is installed.

- all invasive fittings must be properly treated;

- all structural wall should be sealed;

- the sub-floor, which must be clean and dry, should be covered with proper insulation layer consisting of mineral wool insulation, added between the floor joists;

- the entire structure needs to be watertight;

- the product must be kept and stored in dry conditions.

Installation should begin with at the furthest point from the entrance, while the decking must follow a “stretcher-bond” pattern. The boards are pushed over the joints which have been treated with a proper adhesive added both on top of the tongue and bottom of the groove. It is advised that stud partitioning should be built from the sub floor and that flanking strips should be added for improved insulation performance of the walls and floors. Once the entire system has been installed, the boards should be protected from potential damage with a proper finish layer added on top. All skirting must be isolated from the floor surface and new ceiling boards installed prior to installing the system, in order of avoiding potential flanking transmission.

When installed in bathrooms and kitchens, some additional considerations apply. All rigid plumbing connectors that go through the system should be properly insulated from floating and sub floor by adding some flexible sealant to the hole around the services perimeter, cut up to 10mm wider. In order of supporting higher loads, additional support noggins should be installed between the joists, which is also applicable when installing underfloor heating systems in bathroom and kitchen areas.

The product is in compliance with Approved Document E of the Building Regulations.