Isocheck Deep Batten 75mm

- Product Code: A1-1045

- Delivery Time: 3 - 5 days

- Brand: Isomass (Tech. support: 08458383389)

- Model and Size: Deep Batten - 75mm

4.6 out of 5 - Excellent

Isocheck Deep Batten 75mm

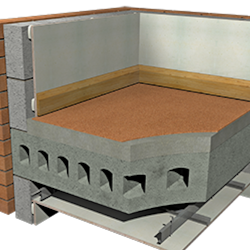

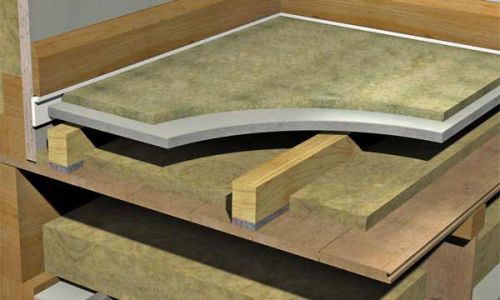

75mm Isocheck Deep Batten is part of a suspended floor system, designed for reducing sound transmission and improving acoustic performance of steel and timber floors. The system is used in new build timber and steel frame constructions, including the possibility of combining it with underfloor heating systems, able to meet the requirements of the Building Regulations, Approved Document E 2003 (including the subsequent amendments in 2004) and the Code for Sustainable Homes. The system includes 15 mm Isopoli or 18mm Isofiba standard 60mm softwood batten, but also available in other sizes, upon request.

CHARACTERISTICS

- Great acoustic properties;

- Able to meet values prescribed by the Approved Document E of the Building Regulations, when installed as part of a complete sound reduction system;

- Includes a FSC certified softwood batten;

- Can be used in combination with the underfloor heating system;

- Can comply with Code for Sustainable Homes.

APPLICATION

Isocheck Deep Batten is applicable over timber floors, especially if there is a masonry or timber frame facade, since if combined with the underfloor heating system, as specified, it can be used to hide accommodated services.

INSTALLATION

Prior to installation of the system, the following considerations must be taken into account:

- the sub-floor must be clean and dry;

- the building must be dried and weatherproof;

- structural floor air passage must be blocked;

- any component of the flooring that is subject to wet conditions must be properly replaced;

- service location must be planned in the early phase of construction;

- the product must be kept and stored in dry conditions.

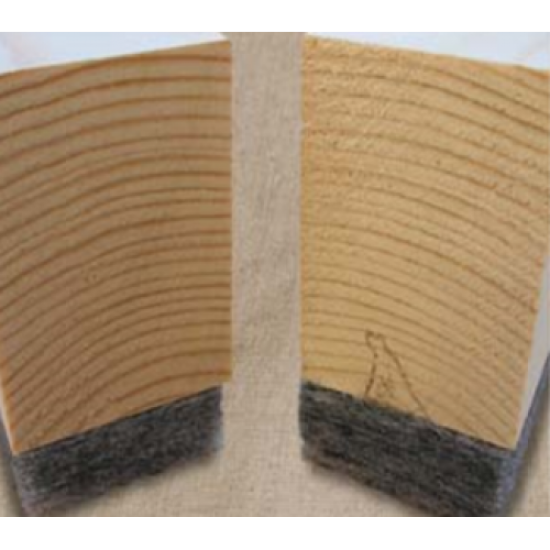

The battens should be laid about 50mm from the wall around the perimeter and then positioned at 400mm centres under standard domestic loading. The position of any no-load bearing partitions should be marked, whereas lightweight ones can be constructed from the timber deck and the double row of battens placed beneath or alternatively a supporting ladder frame of battens should be created. The battens can be positioned either perpendicular to the direction of the structural joists or placed above the main floor joists, laid in the same direction. The battens should be positioned so that the joists leave a gap at the end. The battens should be cut and placed at around 25mm either pipe side. The plaster plank should be laid in a brick-bonded method across the battens and a 10mm gap left clear at the perimeter. The plank should be fixed to the bearer with at least three gypsum nails of appropriate length.

In case of the standard domestic loading and bearers placed at 400mm centres, 18mm chipboard should be fixed with annular ring shank screws or nails. Use appropriate adhesive to glue all grooved (on bottom) and tongued (on top) joints, in order of tightly butting all joints. Prior to fixing the skirting board, flanking strips should be positioned in the perimeter gap and excessive parts cut, but the flanking strips should not be removed once the installation is completed.

CERTIFICATION

The product is in compliance with:

- Approved Document E of the Building Regulations;

- It can comply with Code for Sustainable Homes;

- Robust Detail descriptive FFT1, typically within Robust Detail E-FT-1, E-FT-2, E-FT-3, E-FS-2, E-FC-1, E-FC-7 and E-FS-1.