Novia FF1 Foil Faced Building Paper 1m x 50m Roll

Novia FF1 Foil Faced Building Paper 1m x 50m Roll

- Product Code: A1-2444

- Delivery Time: 1 - 2 days

- Brand: Novia (Tech. support: 01622678952)

- Model and Size: 1m x 50m

- Weight: 15.00kg

Product discontinued.

Click Get Best Price to request a quotation and we will recommended an equivalent product.

Our ratings on 09-05-2025:

4.7 out of 5 - Excellent

4.8 out of 5

Novia FF1 Foil Faced Building Paper 1m x 50m Roll

Width: 1000mm

Weight: 15kg

Length: 50000mm

Novia FF1 Foil Faced Building Paper is a BS 1521 compliant grade of low emissivity, foil-faced, scrim-reinforced, bitumen laminated traditional building paper use as an air leakage and vapour control barrier applications for insulated walls, roofs and floors. It has a very high diffusion moisture barrier capability. Novia FF1 is used in applications where rubber and plastic are unsuitable. It must be professionally installed in conjunction with Novia 2-tape sealing system to ensure a fully airtight seal. 50m roll.

Note: Pallet quantities only. Please inquire

CHARACTERISTICS

- Traditional material for non-plastic and non-rubber VCL applications,

- Bitumen laminated traditional building paper,

- High reflectivity and low emissivity surface that delivers improved R and U-values when installed facing a minimum cavity of 25mm,

- Reinforced multilayer polythene laminate,

- Minimises interstitial condensation,

- Improves the insulation performance,

- CE approved to BS EN 13984,

- Meets the requirements of BS 5250: 2011

- Flame resistant to EN 13501-1 Class E,

- Suitable for use in commercial cladding systems.

APPLICATION

- For wall, roof and floor applications as an air leakage barrier and vapour control layer.

INSTALLATION

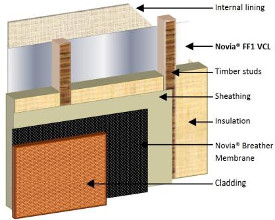

- VCLs should always be installed on the inside within all wall, roof or floor insulated frame applications, and would normally be used in conjunction with Novia external breather membranes which are situated on the cold side (on the outside).

- Fix the membrane to the structure using suitable galvanised or stainless permanent fixings,

- All VCL membrane joints should have a minimum 150mm overlap and be situated on a stud, rafter or timber,

- To improve overall airtightness, butyl tape is pre-applied to all the areas where a fixing is to be made.

- Ensure that the membrane is not damaged during installation, and that all service entry points are properly sealed.

CERTIFICATION

Brand: Novia

Model and Size: 1m x 25m

Delivery Time: 1 - 2 days

Novia BS 1521 Grade Polybit (Polythene Coated A1F) Building Paper is a traditional, polythene coated, reinforced kraft paper bitumen-bonded, building paper laminate for use as a waterproof building paper. It is manufactured with wet-strength kraft paper and meeting the technical requirements of BS 1..

Guide Price: £57.17

£68.60 inc VAT

Brand: Novia

Model and Size: 96mm x 45m

Delivery Time: 1 - 2 days

96mm Novia Aluminium Foil tape is a high tack single-sided tape for use as a lap seal in Gas Barrier DPM installations or for Vapour Control Layer applications in walls and ceilings of insulated constructions. It is also suitable for use in damp proof membrane applications as a single sided lap..

Guide Price: £9.85

£11.82 inc VAT

Brand: Novia

Model and Size: 1.8m x 50m

Delivery Time: 1 - 2 days

Novia 509B Shed Lining Paper is suitable for use in a wide range of garden structures and adds an extra level of protection to your building by creating a wind proof and waterproof outer layer. It is an ideal option for uninsulated garden structure construction and for renovating a current uninsulat..

Guide Price: £117.94

£141.53 inc VAT

Brand: Novia

Model and Size: 1m x 50m - 50m2

Delivery Time: 1 - 2 days

Novia Black+ Supreme Roof and Wall Breather Membrane is a 3-layer high performance, lightweight wall breather membrane for pitched cold and warm roofs, and insulated wall applications. Novia Black+ Supreme Roof and Wall Breather Membrane has excellent Class W1 water resistance while providing high b..

£38.64

£46.37 inc VAT

Brand: Novia

Model and Size: 72mm x 45m

Delivery Time: 1 - 2 days

72mm Novia Aluminium Foil tape is a high tack single-sided tape for use as a lap seal in Gas Barrier DPM installations or for Vapour Control Layer applications in walls and ceilings of insulated constructions. It is also suitable for use in damp proof membrane applications as a single sided lap..

£7.26

£8.71 inc VAT

Brand: Novia

Model and Size: 48mm x 45m

Delivery Time: 1 - 2 days

48mm Novia Aluminium Foil tape is a high tack single-sided tape for use as a lap seal in Gas Barrier DPM installations or for Vapour Control Layer applications in walls and ceilings of insulated constructions. It is also suitable for use in damp proof membrane applications as a single sided lap..

£4.84

£5.81 inc VAT

Brand: Novia

Model and Size: 1.5m x 50m

Delivery Time: 1 - 2 days

Novia VC4000 FR Reflective Vapour Control Layer is a premium quality, high performance, Class B flame resistant, reflective air and vapour control layer (AVCL) in any insulated wall or roof application where high moisture vapour resistance is required. Novia VC4000 FR has a reflectivity of 98%, whic..

Guide Price: £169.68

£203.62 inc VAT