EWI Systems - Insulated Render

Most buildings in UK are constructed with solid walls. They don't have cavities that can be filled or injected with insulation. These solid external walls need to be insulated by adding a layer of insulation to either to the interior face or to the exterior face of the wall. The best method is to insulate the walls on its exterior face. The savings on your heating bills will be bigger, and those savings would have a great impact on your budget.

In a typical building, around 40% of the energy used to heat or cool a room is wasted due to poorly insulated external walls. Correctly chosen external wall insulation (EWI) systems dramatically cut energy loss by wrapping the building in a thermally resistant envelope and also provide lasting protection for the entire structure of the building. The external wall insulation system involves an entire set of different products and accessories, so it is important to make sure that you get all quality products you need from one place. Here at Insulation Shop we provide just that a complete set of high quality insulation products and all necessary accessories for insulating your exterior walls. The best possible building performance can only be achieved if walls are externally insulated.

- External wall is warm and dry, increasing thermal performance and reducing building maintenance

- The heat retention capability of the existing wall is fully utilized

- Removes of cold bridges reducing the risk of condensation, damp and mould

- Eliminates cracking caused by thermal expansion and contraction

- Lightweight construction methods can be used, allowing for fast installation

- Reduces heating costs by up to 40%

- Reduces maintenance costs

- Improves the living environment: - Warmer in Winter - Cool in Summer

- Protects the building fabric and enhances the aesthetics

- Does not encroach on living space

- May increase the value of your property

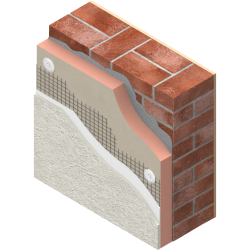

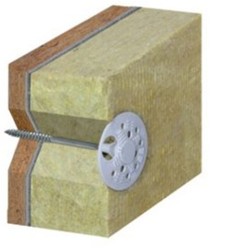

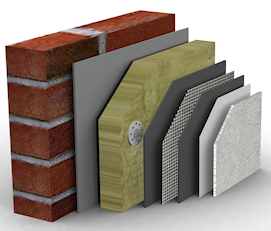

External Wall Insulation (EWI) is a system, which not only insulates, but also protects the exterior of your home. External wall insulation involves fixing a layer of insulation material to the wall, then covering it with a special type of render or cladding. This finish can be smooth, textured, painted, tiled, brick slipped, dry-dashed or paneled.

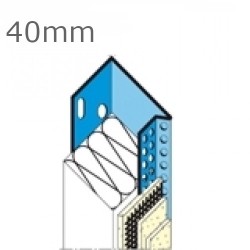

The usual EWI system consists of insulation, adhesive render or base coat, insulation fixings, polypropylene or glass fiber mesh, primers, decorative surface finishes and also beads, trims and flashings.

- The insulation is the main thermal layer, and also the background for applying the adhesive render, basecoat and finishes to. Various types of insulation are available The choice of the insulation is dependent on the required thermal performance, zoning, location and cost. The rigid or semi rigid insulation boards are fixed either directly with adhesive, with insulation fixings, or a combination of both.

- Adhesive renders are applied to the rear of the board in either a dot and dab method, with the perimeter of the board being coated and two slobs in the middle, or with a serrated edge trowel to the entire rear of the insulation board.

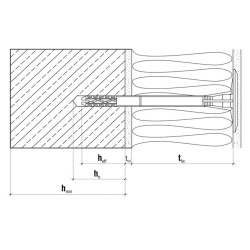

- Insulation fixings used in most EWI systems. These are specified to suit the existing substrate, the height and shape of the building, its location and elevation, and proximity to other buildings. Most times, a combination of adhesive render and insulation fixings are used.

- Most basecoats used are polymer modified cement based renders, which are weatherproof and can accommodate varying degrees of thermal movement. Basecoats are reinforced with a mesh over the top of the insulation layer. The reinforcement layer would spread stresses across the facade surface into the insulation below, provide impact resistance to the system and enhance weatherproofing.

- The final decorative surface finish would provide added weather proofing properties to the building envelope. This finish can be smooth, textured, painted, tiled, brick slipped, dry-dashed, wet-dashed or paneled. It cold be acrylic textures, silicone textures, mosaic textures, mineral renders and brick effect renders.

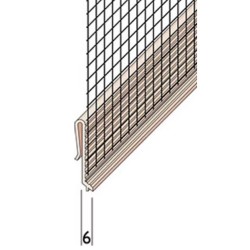

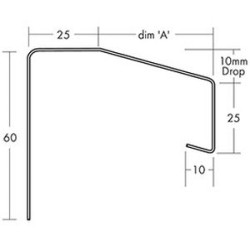

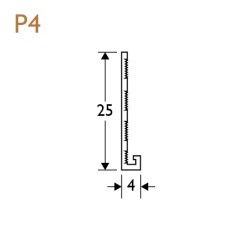

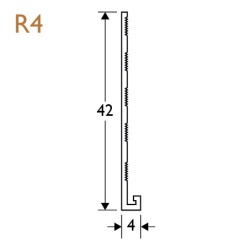

- All EWI systems require the use of beads, trims and flashings. They are used as starters, junctions and closers.

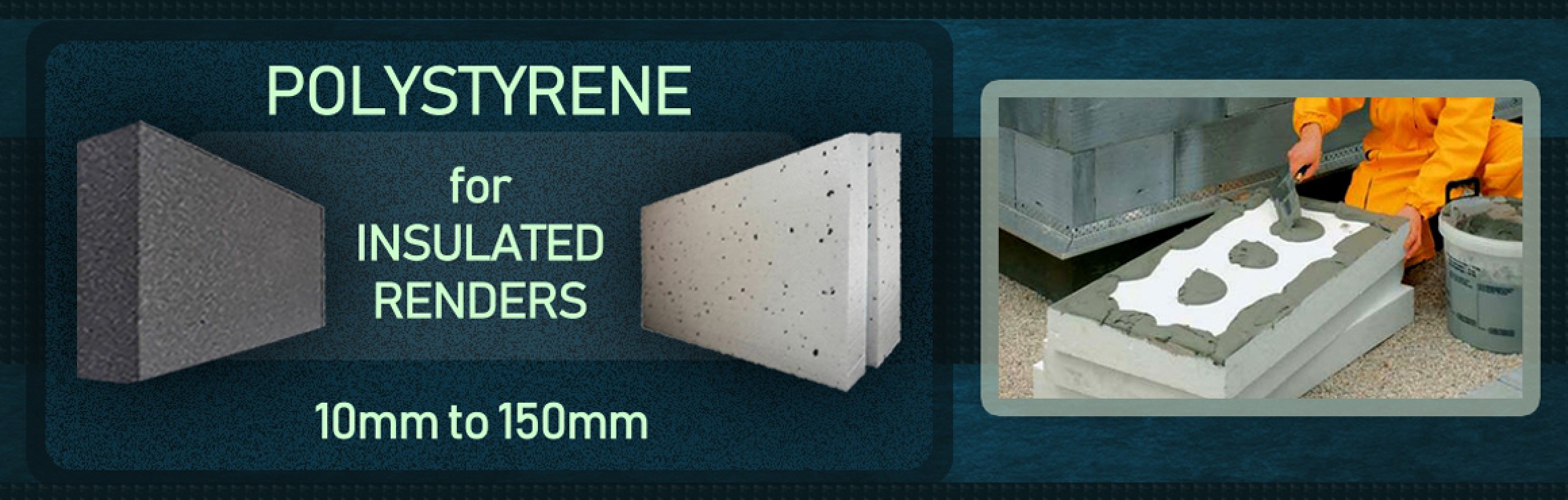

- Expanded polystyrene (EPS) White & Grey,

- Extruded polystyrene (XPS),

- Phenolic,

- Glass wool and Mineral (Stone) wool,

- Polyisocyanurate (PIR)

Expanded Polystyrene (EPS) White & Grey Installation

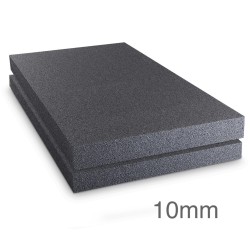

Expanded Polystyrene (EPS) is a lightweight, rigid, plastic foam insulation material, which a cost effective, easy-to-use product for EWI applications. The structure of EPS consists of 98% air. Its initial thermal properties are maintained throughout its working life. It is non-toxic, moisture resistant and rot proof.

Grey Polystyrene (Graphite) is a high quality expanded polystyrene (EPS) board enhanced with integrated graphite within its bead structure. The high-purity graphite particles integrated within the insulation beads reflects radiant heat and significantly improves insulation capability, providing up to 20% greater r-value than traditional white EPS of the same thickness. Warm air always moves towards cold air, In Grey Polystyrene (Graphite) the path taken by warm air moving towards the cold air takes many twists and turns along the way, slowing down the heat transfer, keeping the premises warmer.

- Cost effective - cheapest insulation material in the market

- Easy to cut using a fine tooth saw or hot wire cutter

- The surface can be rasped on site to remove level differences

- Durable, not affected by short exposure to UV or rain

- Long term exposure can cause slight discoloration, but does not affect the thermal performance

- Has a high K-value when compared with other insulations

- Can be used in low rise and high Rise applications and in coastal locations

- Does not absorb moisture and its thermal and mechanical properties are unaffected by damp, humidity or moisture

- 100% recyclable.

- Should be kept away from solvents

- Should not be exposed to naked flame

- Classified as combustible (combustibility is limited due to retardants present)

- Should be stored in protected packaging and away from direct sunlight

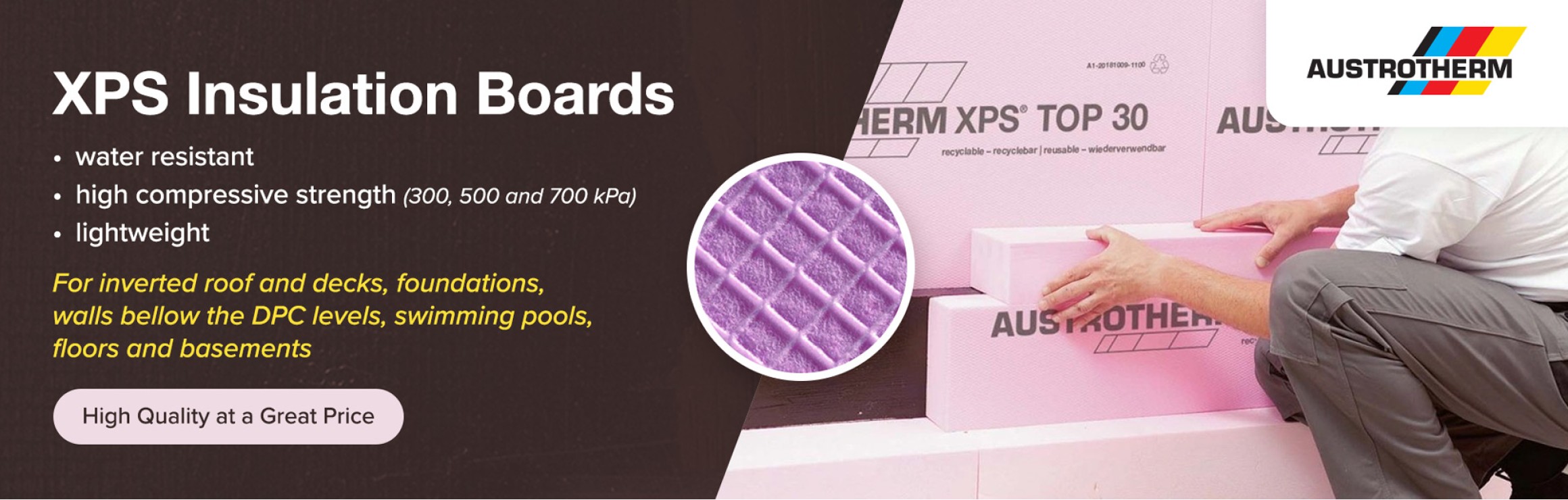

Extruded Polystyrene (XPS) Installation

XPS is a closed cell extruded polystyrene insulation with good thermal and water resisting properties having a high compressive strength. A wide range of thicknesses are available to achieve the thermal values required. Extruded polystyrene can withstand extreme loads. Used mainly below ground applications.

- Able to withstand extreme loads

- Below ground applications

- Easy to cut using a fine tooth saw or hot wire cutter

- Highly water resistant

- Can be stored and installed in severe wet weather conditions with no deterioration during its life

- Durable, not affected by short exposure to UV or rain

- Has a high K-value when compared with other insulations

- Can be used in low rise and high Rise applications and in coastal locations

- Does not absorb moisture and its thermal and mechanical properties are unaffected by damp, humidity or moisture

- 100% recyclable

- Should be kept away from solvents

- Should not be exposed to naked flame

- Classified as combustible (combustibility is limited due to retardants present)

- Can react to PVC cables and cause cables to become brittle, therefore a conduit should be used

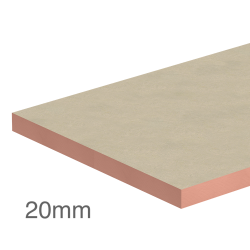

Phenolic Insulation

Rigid phenolic insulation is produced by mixing high solids and phenolic resin with a surface acting agent. The heat created by the reaction evaporates a volatile liquid blowing agent in the mixture which produces a network of small bubbles in the material. This insulating core is bonded to two flexible tissue faced layers. The rigid phenolic insulation offer very good thermal insulating properties due to the very low thermal conductivity of phenolic foam. It can actually be 50% more effective than other common insulation materials. Its low thermal conductivity allows specified thermal performance targets to be achieved with minimal thickness of insulation, and saves space.

Kingspan Kooltherm K5 External Wall Board is a one of the top selling phenolic core external wall insulation boards, applicable to both solid and cavity brick and block walls.

- Offers the best K-value of all the available insulation - thinner boards required

- Easy to cut using a fine tooth saw

- High closed cell content and fine cell structure

- Lightweight, easy to transport , handle and install

- Resistant to fungus and mould growth and will not sustain vermin

- Highly resistant to moisture penetration

- Dimensionally stable and can be cut accurately to achieve a snug fit

- Self extinguishing, low smoke emission

- Can be used in low rise and high Rise applications and in coastal locations

- Should be kept dry

- Should not be used if effected by rain until it has been dried out

- Should not be exposed to naked flame

- Should not be left exposed for long periods of time to direct sunlight and rain

- Classified as combustible (combustibility is limited due to retardants present)

Mineral Fibre - Glass wool, Rock wool Insulation

Glass mineral wool is made from sand and recycled glass, limestone and soda ash. The glass is spun to form millions of fine fibres. A resin is used to bind the long fibres together to form a mat of material giving good tear strength. The density of the product determines whether the insulation is a lightweight quilt supplied in rolls, a flexible slab or a rigid slab, and its thermal insulation value.

Rock wool (also known as mineral wool or stone wool) is manufactured from molten rock in a furnace through which a stream of air or steam is blown at temperature of about 1600 C. The final product creates a mass of fine, intertwined fibres which may contain binder (often food grade starch) and an oil to reduce dusting. When pressed into rolls and sheets their ability to partition air makes them excellent heat insulators and sound absorbers. The insulation is produced in a variety of densities according to format and function. High quality Rockwool Frontrock Super Dual Density External Wall Insulation Slab are available at Insulation Shop.

- The only insulation to be classed as non-combustible

- Offers good K-values

- Production emissions within UK legal defined limits

- Reduces overall environmental impact and formaldehyde-free

- Non skin irritant

- Easy to handle and work

- Resistant to rot

- Excellent acoustic and thermal properties

- Recyclable

- Can be used in low rise and high Rise applications and in coastal locations

- Should be stored on a flat, covered, protected surface

- Should be kept dry

- Should not be left exposed for long periods of time to rain

- Should not be used if effected by rain until it has been dried out

- Should limit the area of application of the boards and to basecoat at the earliest chance to avoid the boards becoming wet

- Acrylic renders

- Mineral renders

- Mosaic renders

- Silicone renders

Acrylic render

Acrylic render is a finishing coat for render, containing acrylic aggregates to display an attractive finish. It is much more resistant to cracking than other types of render. Acrylic render is available in a wide range of colours and textures ranging from 1mm to 3mm aggregate size.Acrylic render is also fast drying, taking only two days to cure and dry while traditional renders can take up to 28 days. Acrylic render can be used to cover up small hairline cracks in masonry surfaces. The minute reinforcing fibres in Acrylic renders produce an incredibly tough and durable finish. It is permeable to water vapours and allows the substrates (brick etc) to breathe. It is also resistant to efflorescence (the white salts that sometimes leak from brickwork). Acrylic render can be trowelled on or rolled or even sprayed onto a surface. Two coats are generally applied.

- Easy to apply

- Easy to clean

- Lasts longer

- Covers hairline cracks

- Water vapour permeable

- Allows substrates to breathe

- Resistant to efflorescence

- Resisting driving rain

- Resists UV

- Can be trowelled on or rolled or even sprayed

- Available in a wide range of colours and textures

- Should be cleaned of fallen leaves - might grow algae

Mineral render

Mineral Render is eco-friendly, manufactured from natural materials such as mineral aggregates, and white marble grain. It is available with a rolled texture in 2, 3 and 4mm grain sizes. Mineral Render is highly damage resistant and also is Class 0 surface spread of flame. Mineral render contains cement contact allowing the product to set quicker, so it can be easily used during lower temperature periods.

- Easy to apply

- Easy to clean

- Highly damage resistant

- Covers hairline cracks

- Sets quickly - contains cement

- Can be used during lower temperature periods

- Fire resistant

- Allows substrates to breathe

- Resisting driving rain

- Resists UV

- Available in a wide range of colours and textures

- Made entirely from natural materials

Mosaic render

Flexible and easy to clean render with increased scratch resistance and covering ability. Suitable for indoor and outdoor use on walls exposed to high wear: at plinths, entrances, hallways, window and door reveals. Sealing component: transparent resins. Filler: coloured quartz stone. Can be applied and smoothed with stainless steel trowels. Produces a glassy, colourful coat upon setting. Mosaic render can be used on concrete substrates and traditional plasters etc.

- Easy to apply and clean

- Can be applied and smoothed with stainless steel trowels

- Increased scratch resistance

- Covers hairline cracks

- Sets quickly - contains cement

- Can be used during lower temperature periods

- Fire resistant

- Allows substrates to breathe

- Resisting driving rain

- Resists UV

- Available in a wide range of colours and textures

- Might collect dirt

Silicone render (Polymer render)

Polymer render is a cement based system with specially selected polymers added to the mix. These polymers make the finished coat strong yet flexible, allowing them to be used on any substrate. Polymer renders incorporate silicone water repellents as an integral part of the cement based render system. This silicone technology allow water vapour to pass through the render, letting the substrate breathe. The use of nylon reinforced base coats provides a high strength base for the finish coat. Polymer render is available as one coat render, eliminating the need for a base coat. Polymer renders come in a wide range of colours and can be finished in different textures, from a flat sponged float finish or a rougher scraped finish as well as Pebble Dash. They are usually premixed and only require the addition of clean water to produce the final product. This ensures the quality of the render remains consistent and ensures a superior finish.

- Tough cement based render

- Can be applied on a range of substrates

- Increased scratch resistance

- Covers hairline cracks

- Allows substrates to breathe

- Textures could be smooth or dry or wet dashed

- Fire resistant

- Available premixed

- Resisting driving rain

- Resists UV

- Might collect dirt

Installation of EWI Systems

To correctly specify which insulation system to use, the existing wall envelope should be examined.

- Check the walls for any visual defects

- Check for rising damp and its causes

- Check for existing movement joints

- Carry out a line and level survey to determine if a levelling coat is required

- Check for efflorescence (the white salts that sometimes leak from brickwork)

- Check the need for repositioning of, temporary removal or extension of services such as electricity, gas, telephone, TV or internet

- Also, check if building permission is required

The drawings and specification would include

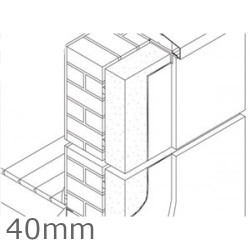

- Damp proof course level

- Position of starter tracks and render beads

- Position and amount of reinforcement scrim, corner mesh and scrims for corners and openings

- Detailing of doors, windows, eaves, projecting balconies, coping details and any other extension

- Location and positioning of beads and trims, flashing details, window sill and door sill details and architectural features

- Location and type of weather seals, silicone sealants are to be used

- Location of any other wall attachments such as telephone lines, TV, satellite dishes

- Type of external wall insulation

- Types of adhesives, base coats, reinforcement mesh, insulation fixings and renders

- The wall should be cleaned from dirt, grime, algae etc, and be allowed to fully dry out,

- If a building has an existing rendered finish, and If the render is in a poor condition--by trapping water, transmitting damp, and not allowing the existing building to breathe, then it is better to remove the render

- Check the line and level of any existing building, and the uneven surface of the wall should be corrected

- Carry out a pull-out test for adhesives and insulation fixings

- EWI boards should be protected from adverse weather, direct sunlight and possible impact damage

- Insulation work should only done in dry conditions

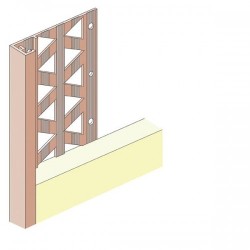

- Boards should be laid in a staggered pattern

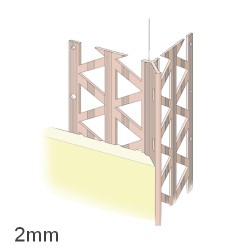

- They should be staggered at the edges of buildings so that they form a toothed finish

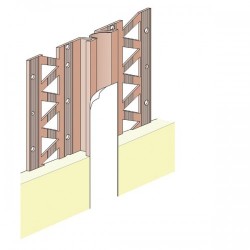

- The boards should be cut in an L shape around the corners of openings

- No small cuts of boards are allowed be used

- Gaps between boards should be limited, and if that happens the gaps should be filled tight fit with the same type of insulation

- Boards should be level so that the basecoat and decorative finish are installed on a flat surface

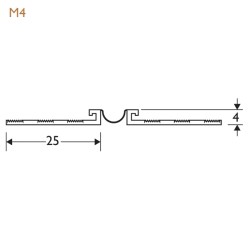

- Beads and trims to be fixed at given locations, starter tracks at the beginning, beads and trims as the work progresses

- Adhesive renders should be applied to the rear of the board, and should follow either a dot and dab method to the board edges, or a fully applied adhesive using a serrated trowel

- Mechanical anchors, insulation fixings should be used as per specification

- Insulation fixings should be installed at 90 degrees from the wall face, and the washer head sitting flush with the insulation board face

- Application of basecoat should only be carried out when the weather is fine and free from rain

- In a thin basecoat system, the application of any mesh should occur at the first basecoat stage

- Meshes for the thick basecoat system are generally metal laths types and are fixed to the insulation prior to first base coat

- Meshes should be installed into the wet basecoat, using the back of a steel trowel and pushed in, so that they sit in the top third

- Meshes should be continuous, and should have a minimum 100mm lap with the adjacent mesh to ensure strength and continuity of the basecoat

- Once the basecoat has been applied, it should be left to cure to receive the final finish

- Finishes should only be applied in good weather and within ambient temperatures (5-30 C)

- Finishes should be stored in areas that can achieve a constant temperature, and should not drop below 5C

- Textured finishes should be applied with a steel trowel and rubbed with a plastic or nylon trowel to reveal the aggregate

- Junctions are finished with a mastic sealant, however its use should be kept to a minimum as they have a short life cycle and will need to be maintained at regular intervals

- General good practice would be to fill the gap with the silicone sealant and the final finish taken over the top

Typical installation examples

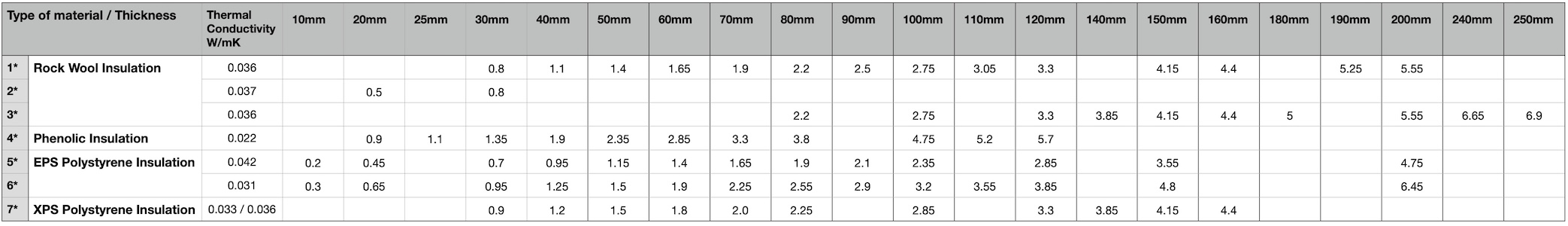

R-value Comparison Chart for External Wall Insulation available at Insulation Shop

Legend

1* Rockwool Dual Density Slab for Insulated Renders

2* Rockwool Frontrock S External Wall Insulation Slab

3* Rockwool Frontrock Super Dual Density External Wall Insulation Slab

4* Kingspan Kooltherm K5 External Board

5* White Polystyrene Board (EPS) for External Wall Insulation