Insulated OSB

Insulated OSB panels are a highly effective and increasingly popular composite building material that seamlessly combines the structural performance of Oriented Strand Board (OSB) with the thermal efficiency of rigid insulation. These panels offer a versatile and streamlined solution for creating robust, energy-efficient building envelopes, particularly favoured in modern construction methods.

An insulated OSB panel is typically a factory-fabricated composite unit, comprising two primary elements:

- OSB (Oriented Strand Board) Facings: These form the durable, structural outer layers of the panel. OSB is an engineered wood product made by compressing precisely oriented strands of wood with resins at high temperatures. Its characteristic appearance of interweaving wood strands provides excellent strength and stiffness. Common types like OSB/3 are suitable for humid conditions.

- Rigid Insulation Core: Sandwiched and securely bonded between the two OSB facings, this insulation layer provides the thermal performance. Common insulation materials include:

- PIR (Polyisocyanurate): Highly valued for its superior thermal efficiency (low U-values) in a relatively thin profile. Often faced with foil for enhanced performance and vapour control.

- EPS (Expanded Polystyrene): A lightweight and cost-effective option, offering good thermal properties.

- Phenolic Foam: Provides exceptionally high thermal performance, ideal where maximum insulation in minimal thickness is required.

Key Benefits

- Dual Functionality: Provides both robust structural integrity and high levels of thermal insulation in a single prefabricated unit, simplifying and accelerating the construction process.

- Excellent Thermal Performance: Significantly improves the U-value of walls, roofs, and floors, leading to substantial reductions in heat loss, lower energy consumption, and compliance with stringent energy efficiency regulations.

- Structural Strength: The OSB facings contribute excellent racking strength and stiffness, making them ideal for load-bearing walls, roofs, and floors, particularly in timber-frame and modular construction.

- Speed of Installation: As large, pre-engineered panels, they allow for rapid enclosure of the building, significantly reducing on-site labour and overall construction time.

- Space-Saving: By integrating insulation within the structural panel, they minimise overall wall or roof thickness compared to traditional multi-layer build-ups.

- Reduced Cold Bridging: The continuous insulation core significantly reduces thermal bridging found in traditional stick-built framing.

- Reduced Waste: Factory fabrication leads to less on-site waste.

Applications

Insulated OSB panels are highly versatile and widely used in:

- Walls: As structural and insulating external wall elements in timber-frame houses, extensions, and commercial buildings.

- Roofs: For warm roof constructions (pitched or flat), providing both the structural deck and insulation.

- Floors: For suspended ground floors or upper floors where both structural decking and thermal performance are required.

- Modular and Prefabricated Construction: Their pre-engineered nature is perfectly suited for off-site manufacturing and rapid assembly.

- New Build and Retrofit Projects: Contributing significantly to energy-efficient building envelopes.

CHOOSE MANUFACTURERS

Model: 2400x1200 - 2.88m2

Delivery Time: 1 - 5 working days

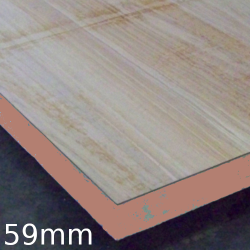

59mm Thermal Render Panel is a composite board consists of a 9mm OSB board bonded to a 50mm Kooltherm K5 phenolic foam core that can take the render. The Thermal Render Board provides a high level of thermal insulation, render board and a quicker construction saving money and time. It also saves the..

Brand: Various

Model: 1200mm x 2400mm - 2.88m2

Delivery Time: 4 - 7 days

33mm Structural Insulated Panel (SIP) comprises a 15mm thick core of rigid Polyisocyanurate (PIR) insulation sandwiched between two 9mm thick Oriented Strand Board (OSB) sheets. The OSB sheets are bonded to the PIR core under high pressure, creating a strong, rigid, and monolithic unit. This sandwic..

Brand: Various

Model: 1200mm x 2400mm - 2.88m2

Delivery Time: 4 - 7 days

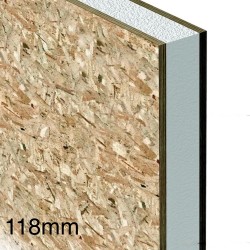

118mm Structural Insulated Panel (SIP) consist of a 100mm Expanded Polystyrene (EPS) core sandwiched between two 9mm Oriented Strand Board (OSB) sheets. This advanced component offers superior strength, durability, and insulation. The OSB acts as a rigid skin, much like the flanges of an I-beam..

Guide Price: £70.78

£84.94 inc VAT

Brand: Various

Model: 1200mm x 2400mm - 2.88m2

Delivery Time: 4 - 7 days

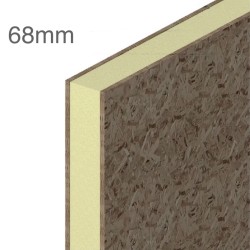

68mm Structural Insulated Panel (SIP) comprises a 50mm thick core of rigid Phenolic Core sandwiched between two 9mm thick Oriented Strand Board (OSB) sheets. It is an advanced building component designed for high-performance and energy-efficient construction. This sandwich panel ensures superior str..

Brand: Unilin (prev. Xtratherm)

Model: 2400mm x 1200mm - 2.88m2

Delivery Time: 1-3 working days

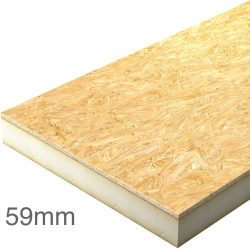

59mm Unilin Plydeck Flat Roof Board is a high-performance composite board designed for flat roof applications. It comprises a 50mm rigid polyisocyanurate (PIR) insulation board directly bonded to a 9mm OSB board. This combination provides both high levels of thermal insulation and a robust decking s..

Showing 1 to 5 of 5 (1 Pages)