Reinforced and Tile Backer XPS Boards

Reinforced XPS Boards

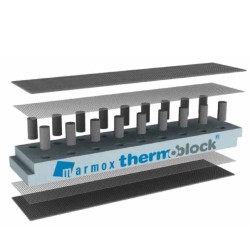

Reinforced Extruded Polystyrene (XPS) boards are high-performance insulation panels designed to provide exceptional thermal resistance and structural strength. These boards are manufactured through a process of extruding polystyrene resin, resulting in a closed-cell, rigid foam with superior moisture resistance and durability. The reinforcement aspect typically involves the integration of a fibreglass mesh or other strengthening materials embedded within or laminated onto the board surface, enhancing its mechanical properties.

Reinforced XPS boards are widely used in construction applications where both insulation and load-bearing capacity are required. Their robust nature makes them suitable for use in floors, walls, and roofs, particularly in environments exposed to moisture or mechanical stress. The boards offer excellent compressive strength, making them ideal for underfloor heating systems, flat roofs, and external wall insulation systems (EWIS). Additionally, their resistance to water absorption ensures long-term performance without degradation.

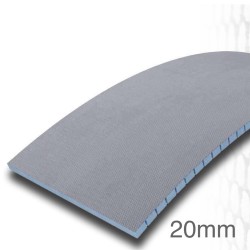

Tile Backer XPS Boards

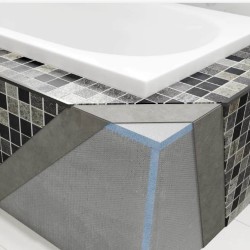

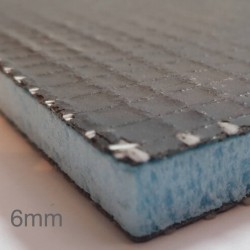

Tile Backer XPS boards are specialised insulation boards designed specifically to serve as a stable and moisture-resistant substrate for tiling applications. These boards combine the thermal insulation properties of XPS with a reinforced surface that provides a reliable base for the adhesion of tiles in wet and dry areas alike.

Typically, Tile Backer XPS boards feature a smooth or textured surface that promotes strong bonding with tile adhesives and grout. Their closed-cell structure prevents water ingress, making them particularly suitable for use in bathrooms, kitchens, swimming pools, and other areas prone to moisture exposure. The boards are lightweight yet sturdy, facilitating easy handling and installation while maintaining dimensional stability under load.

Key Characteristics:

- Reinforced XPS Boards

- Engineered to withstand significant loads, making them suitable for structural applications.

- Excellent thermal resistance (high R-values), helping to improve energy efficiency in buildings.

- The closed-cell structure prevents water absorption, ensuring durability and preventing mould or rot.

- Incorporation of fibreglass mesh or similar materials enhances mechanical strength and impact resistance.

- These boards maintain their shape and performance under varying environmental conditions.

- Despite their strength, they are easy to handle and install.

- Resistant to many chemicals, which adds to their longevity in harsh environments.

- Tile Backer XPS Boards

- Closed-cell foam structure prevents water ingress, ideal for wet areas.

- Designed with a surface that promotes strong adhesion of tile adhesives and grout.

- Offers effective insulation to reduce heat loss through tiled surfaces.

- Lightweight and easy to cut.

- Maintains flatness and integrity under tile weight and environmental changes.

- Suitable for use with a wide variety of tile types, including ceramic, porcelain, and natural stone.

Applications:

- Reinforced XPS Boards

- Ideal for use under screeds and concrete slabs, including underfloor heating systems.

- Suitable for flat roofs and inverted roof systems where load-bearing insulation is required.

- Used in external wall insulation systems (EWIS) to improve thermal performance.

- Employed in road construction, bridge decks, and other infrastructure projects requiring durable insulation.

- Provides insulation and moisture protection in below-ground applications.

- Tile Backer XPS Boards

- Provides a stable, waterproof substrate for tiling in showers, baths, and wet areas.

- Used behind tiled splashbacks and countertops to prevent moisture damage.

- Ideal for tiling in areas with constant water exposure.

- Used as an underlayment to improve insulation and prevent cracking in tiled floors.

- Enhances durability and longevity of tiled surfaces in both new builds and refurbishments.