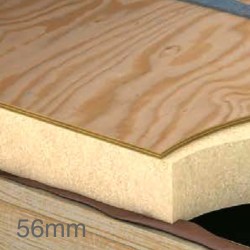

Insulated Plywood

Insulated plywood, often referred to as structural thermal panels or insulated boarding, is a high-performance, composite building material designed to provide both structural integrity and enhanced thermal insulation in a single, convenient unit. It offers a practical solution for applications where a robust, load-bearing surface is required alongside significant improvements in thermal efficiency.

An insulated plywood panel is typically created by factory-bonding two primary components:

- Plywood Substrate: This forms the primary structural layer and the durable surface. It can be various types of plywood, such as:

- Plywood (Softwood or Hardwood): Offering different levels of strength and resistance, suitable for a range of applications.

- Moisture-Resistant or External Grade Plywood: Used where exposure to moisture is a concern (e.g., flat roofs, certain flooring applications).

- Rigid Insulation Layer: Bonded to one face of the plywood, this layer provides the thermal performance. Common insulation materials used include:

- PIR (Polyisocyanurate): Highly efficient with excellent thermal conductivity, providing high insulation values in a relatively thin profile. Often faced with foil.

- EPS (Expanded Polystyrene): A lightweight and cost-effective insulation with good thermal properties.

- Phenolic Foam: Offers very high thermal performance, often chosen when space is extremely limited.

- Mineral Wool: Can be used for combined thermal and acoustic performance.

Depending on the specific product and application, some insulated plywood panels may also incorporate an integrated vapour control layer (VCL), usually a foil facing, to manage moisture movement and prevent condensation within the building fabric.

Key Benefits

- Provides both structural strength and high levels of thermal insulation in one easy-to-handle board, streamlining construction.

- Significantly improves the U-value of the building element, reducing heat loss, contributing to lower energy consumption, and meeting demanding thermal regulations.

- By combining layers, it minimises the overall thickness of the construction compared to separate insulation and boarding systems, which is beneficial where space is at a premium.

- As a single composite board, installation is faster and more efficient, reducing labour time on site.

- The plywood layer provides a robust, load-bearing surface, making it suitable for floors and roofs.

- Helps to minimise thermal bridging when properly installed.

- Certain types, particularly those for flat roofing, offer excellent moisture resistance.

Applications

Insulated plywood panels are highly versatile and widely used in:

- Flooring Systems.

- Flat Roofing.

- Wall Linings.

- Modular and Off-Site Construction.

- New Build and Renovation Projects.