Plasterboards with PIR Insulation

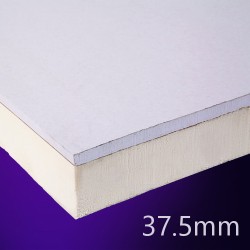

Upgrade your interiors with Plasterboards featuring PIR Insulation – the smart, space-saving solution that combines style, comfort, and efficiency. These innovative boards pair high-performance PIR (polyisocyanurate) insulation with a smooth plasterboard finish, offering both excellent thermal protection and a surface ready for decorating. Designed to enhance energy efficiency and reduce heat loss, they’re ideal for walls, ceilings, and roofs in both new-build and renovation projects. The result is a warmer, more comfortable environment with lower energy costs and a cleaner finish. Lightweight, durable, and easy to install, our plasterboards with PIR insulation simplify construction by combining two essential layers into one convenient product. Whether you’re improving a home, office, or commercial space, they deliver lasting performance and a professional finish – all in one step.

Key Characteristics

- High thermal performance – features a rigid PIR insulation core to significantly reduce heat loss.

- Smooth plasterboard finish – ready for painting or wallpapering for a clean, professional look.

- Space-saving design – combines insulation and plasterboard in one product, reducing wall thickness.

- Lightweight and easy to handle – simplifies installation on walls, ceilings, and roofs.

- Energy efficient – helps to lower heating costs and improve overall building performance.

- Durable and long-lasting – provides a robust internal lining with reliable thermal protection.

- Suitable for new-builds and refurbishments – ideal for upgrading thermal performance in any project.

- Compliant with building regulations – meets modern standards for insulation and fire safety.

- Multiple thickness options available – to suit a range of performance and design requirements.

Where to Install

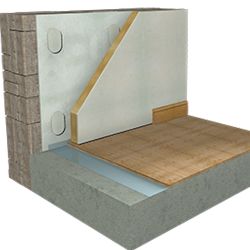

- Internal walls – ideal for upgrading thermal performance in partition or external-facing walls.

- Ceilings – helps improve insulation and reduce heat loss through upper storeys.

- Pitched roofs – perfect for loft conversions and attic spaces where insulation depth is limited.

- Dormer cheeks – provides both insulation and a smooth internal finish in roof extensions.

- Room-in-roof applications – maximises comfort and energy efficiency in converted roof spaces.

- Refurbishment projects – easy to retrofit onto existing surfaces to enhance energy performance.

- Timber or metal stud systems – compatible with common framing methods for quick installation.

- Direct bonding to masonry walls – can be fixed using adhesive for a clean and efficient finish.

Fitting Methods

- Mechanical Fixings (with or without Battens)

Plasterboards with PIR insulation can be securely fixed to walls or ceilings using mechanical fixings. They may be attached directly to the substrate or to timber or metal battens, depending on the project requirements. This method ensures a firm, long-lasting installation and allows for adjustments to uneven surfaces or services concealed behind the boards.

- Dot and Dab (Adhesive Bonding)

Alternatively, boards can be fitted directly to masonry walls using the dot and dab technique. Adhesive is applied in dabs across the surface, allowing quick and straightforward installation with minimal disruption. This method is particularly effective for refurbishment projects, providing a smooth internal finish and improved thermal performance without the need for additional framing.