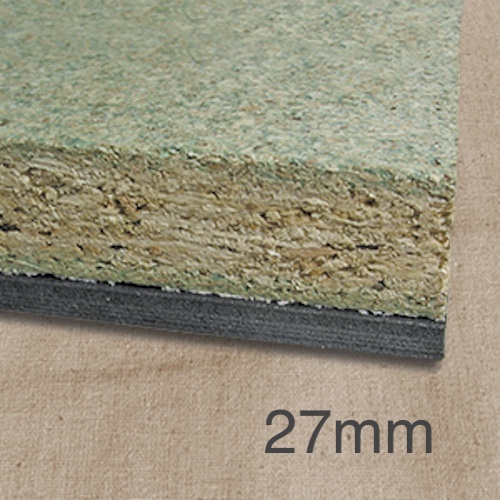

27mm Isocheck 27C Concrete Floor Acoustic Board - 2400mm x 600mm

Guide Price

27mm Isocheck 27C Concrete Floor Acoustic Board - 2400mm x 600mm

Guide Price: £37.04 (£44.45 inc VAT)

Price per m2: £25.72/m2 (£30.87 inc VAT)

5 or more £36.44 (£43.73 inc VAT)

10 or more £35.84 (£43.01 inc VAT)

20 or more £34.91 (£41.89 inc VAT)

- Product Code: A1-1040

- Delivery Time: 3 - 5 days

- Brand: Isomass (Tech. support: 08458383389)

- Model: 600x2400mm - 1.44m2

- Weight: 22.80kg

Our ratings on 27-01-2026:

4.8 out of 5

27mm Isocheck 27C Concrete Floor Acoustic Board - 2400mm x 600mm

Width: 600mm

Length: 2400mm

Coverage: 1.44m2

Weight/m2: 15.8kg

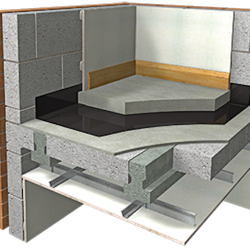

27mm Isocheck 27C is an overlay platform system, designed for reducing sound transmission, including impact sound transmission and improving acoustic performance of concrete floors. Isocheck 27C is used new build, refurbishment and conversions of concrete floors, able to meet the requirements of the Building Regulations, Approved Document E 2003 (including the subsequent amendments in 2004 and 2010) but also in compliance with the Robust Detail. Isocheck 27C consists of a 22mm moisture resistant P5 V313 chipboard bonded to 5.5mm cross linked Isopoli.

CHARACTERISTICS

- Reduces impact sound transmission,

- Reduces airborne sound transmission,

- Able to meet values prescribed by the Approved Document E of the Building Regulations,

- Consists of a moisture-resistant P5 V313 chipboard and 5.5mm cross linked Isopoli,

- Robust Detail compliant;

- Can comply with Code for Sustainable Homes.

APPLICATION

- To be used over concrete floors for conversions, refurbishments or new build with a new ceiling

INSTALLATION

- Installation of isocheck should not commence until roof, window glazing and wet trades are completed and the structure is watertight.

- Floor should be a level screed / concrete with a smooth surface, or an in-situ concrete base. The floors should be level, sufficiently dry and swept clean

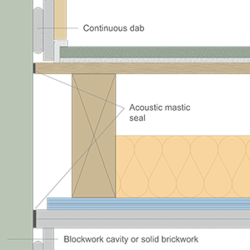

- Apply Isocheck Acoustic Angled Flanking Band on the edges of the Isocheck boards just before they are pushed against the perimeter walls to isolate the board from the wall.

- Board fitting should begin at the furthest point from the entrance and marked out so as not to finish with any panels less than 200mm wide.

- The decking must be laid in broken bond pattern, with all joints glued and staggered.

- No Mechanical fixings should be used.

- Isocheck adhesive is applied to both the top of the tongue and the bottom of the groove on each side of each joint.

- The boards are then pushed tightly together. Surplus adhesive should be wiped away from the surface with a damp cloth.

CERTIFICATION

- Complies with New Build Robust Detail descriptive FFT5 within E-FC-1, E-FC-2 and E-FS-1.

Brand: Isomass

Model: 1200mm x 1500mm - 1.8m2

Delivery Time: 1 - 2 days

40mm x 1200mm x 1500mm Isocheck Absorba Ceiling and Wall Panels are designed to absorb sound and reduce reverberation noise. The tiles comprise a fibreglass core with a white speckled laminated coating. They also have reinforced bevel edges contributing to allowing unique wall and ceiling designs. T..

Brand: Isomass

Model: 1200x600mm - 0.72m2

Delivery Time: 3 - 5 days

15mm Isocheck 15T is an overlay platform system bonded direct to floorboards, designed for reducing sound transmission and improving acoustic performance of traditional timber joisted floors. Isocheck 15T is used in new build, refurbishment and conversion applications, able to also reduce impac..

Guide Price: £20.12

£24.14 inc VAT

Brand: Isomass

Model: 1.2m x 12.5m - 15m2

Delivery Time: 2 - 3 working days

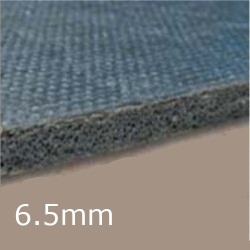

6.5mm Isocheck Impact Mat 100 is made from recycled rubber and designed to reduce sound transmission through timber floors and staircases. It has give an excellent impact improvement and has dynamic stiffness - structural memory. It is ideal for floor upgrades to improve sound reduction on stairs an..

Brand: Isomass

Model: 180x1250mm

Delivery Time: 3 - 5 days

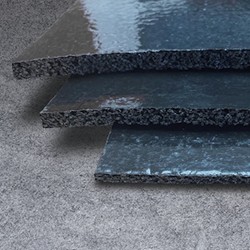

180mm Isocheck Re-Mat Acoustic Isolation Strips are used to reduce structure borne noise when installed beneath block work walls, separating concrete floors from the walls. The strips are made from a rubber crumb, providing minimal creep and great structural stability. The strips are available in di..

Brand: Isomass

Model: 600x2400mm - 1.44m2

Delivery Time: 3 - 5 days

23mm Isocheck Primo HL is an overlay platform system, designed for reducing sound transmission and improving acoustic performance of composite and traditional steel and timber joisted floors in kitchen and bathroom areas. The system is used in masonry and timber frame new build, kitchen and bathroom..

Guide Price: £34.15

£40.98 inc VAT

Brand: Isomass

Model: 1m x 15m - 15m2

Delivery Time: 3 - 5 days

6mm Isocheck ResiScreed 6 is an under screed mat made from rubber crumb bonded to a DPM fibreglass backing to reduce the impact sound transmission through concrete floors. It is designed to be placed directly beneath the screed to isolate the screed from the structural sub floor.CHARACTERISTICSA rec..

Related Products

Brand: Isomass

Model: 600x1200mm - 0.72m2

Delivery Time: 3 - 5 days

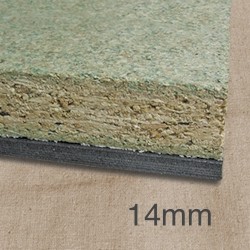

14mm Isocheck 14C is an overlay platform system, designed for reducing sound transmission, including impact sound transmission and improving acou..

Guide Price: £18.32

£21.98 inc VAT

Brand: Isomass

Model: 600mm x 2400mm - 1.44m2

Delivery Time: 3 - 5 days

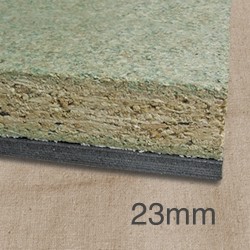

23mm Isocheck 23C is an overlay platform system, designed for reducing sound transmission, including impact sound transmission and improving acou..

Guide Price: £44.03

£52.84 inc VAT

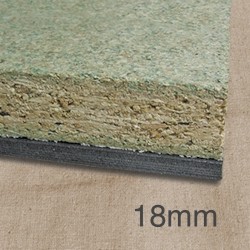

Brand: Isomass

Model: 2400mm x 600mm - 1.44m2

Delivery Time: 3 - 5 days

18mm Isocheck 18C is an overlay platform system, designed for reducing sound transmission, including impact sound transmission and improving acou..