19mm British Gypsum Gyproc Plank Plasterboard

19mm British Gypsum Gyproc Plank Plasterboard

Price: £14.06 (£16.87 inc VAT)

Price per m2: £9.76/m2 (£11.72 inc VAT)

- Product Code: A1-1096

- Delivery Time: 2 - 3 working days

- Brand: British Gypsum (Tech. support: 01159456123)

- Model and Size: 2400x600 - 1.44m2

- Weight: 21.60kg

Our ratings on 27-11-2025:

4.8 out of 5

19mm British Gypsum Gyproc Plank Plasterboard

Width: 600mm

Length: 2400mm

Density: 789.5kg/m3

Weight/m2: 15kg

Weight: 21.6kg

Thermal Conductivity: 0.190W/mK

R-Value: 0.1m2K/W

Fire Rating (Reaction to Fire): A2(Limited combustibility)

Surface Spread of Flame: Class 1

19mm Gyproc Plank Plasterboard is a standard wallboard made of aerated gypsum core bonded to ivory or brown face paper liners, available in both tapered and square edge versions, used for drylining internal surfaces and providing a level of soundproofing when used as a part of specific Gyproc systems. Offers a level of fire resistance when exposed to high temperatures and can be exposed to freezing temperatures, without the risk of being damaged. It can be exposed to freezing temperatures, without the risk of being damaged, however cannot be used to stop damp and moisture.

APPLICATION

- For walls and ceilings,

- As an internal layer in a number of systems including GypFloor silent, GypWall audio and GypWall quiet systems.

- Enables a speedier installation of walls, partitions and ceilings,

- Can be easily fixed to timber and metal partitions by mechanical fixings and to masonry substrates by drywall adhesive,

- Good for cutting down noise transmission particularly airborne sounds due to its additional thickness,

- Typically used in schools, hospitals, cinemas and in old and new-build homes for enhanced sound insulation performance of internal floors.

INSTALLATION

- The boards can be cut with plasterboard saw or sharp knife,

- The boards should be fixed with decorative side facing out,

- Boards should be butted together but never forced into position,

- Fixings should be installed at least 13mm from cut edges and at least 10mm from bound edges.

CERTIFICATION

- Certified to BES 6001 achieving a rating of Excellent

- ISO 9001:2008 Quality Management System,

- ISO 14001:2004 Environmental Management System,

- BS OHSAS 18001:2007 Occupational Health and Safety Management.

Brand: British Gypsum

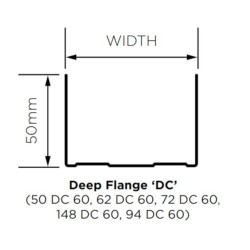

Model and Size: 72 DC 60 - 3.6 m

Delivery Time: 2 - 3 working days

British Gypsum Gypframe 72 DC 60 Deep Flange Floor & Ceiling Channel is used for securing wall studs in ceiling and floor junctions for partition heights over 4200mm up to 8000mm. The product is specially applicable to constructions where better impact resistance and deflection he..

£224.00

£268.80 inc VAT

Brand: British Gypsum

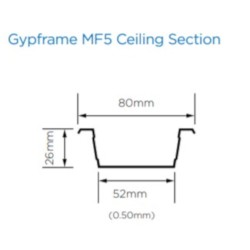

Model and Size: MF5 - 3.6 m

Delivery Time: 2 - 3 working days

Casoline MF5 Ceiling Section is one of the Casoline MF ceiling accessories, used to provide flat or curved seamless suspended ceilings. The product is used as the secondary support section under MF7 Primary Support Channel. Once the primary grid is formed, MF5 secondary section is formed at right an..

£8.60

£10.32 inc VAT

Brand: British Gypsum

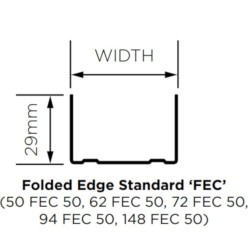

Model and Size: 148 FEC 50 - 3.6 m

Delivery Time: 2 - 4 days

British Gypsum Gypframe 148 FEC 50 Folded Edge Standard Floor & Ceiling Channel is the most commonly used product for securing wall studs in ceiling and floor junctions for partition heights of up to 4200mm. They are made using the UltraSteel process providing a more stabile ..

£145.97

£175.16 inc VAT

Brand: British Gypsum

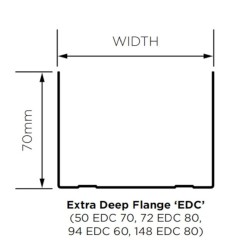

Model and Size: 94 EDC 70 - 3.6 m

Delivery Time: 2 - 3 working days

British Gypsum Gypframe 94 EDC 70 Extra Deep Flange Floor & Ceiling Channel is used for securing wall studs in ceiling and floor junctions for partition heights over 4200mm up to 8000mm. The product is specially applicable to constructions where better impact resistance and d..

Guide Price: £29.50

£35.40 inc VAT

Brand: British Gypsum

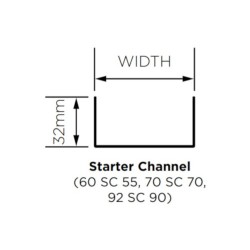

Model and Size: 92 SC 90 - 5 m

Delivery Time: 3 - 4 days

British Gypsum Gypframe Shaftwall 92 SC 90 5 m Starter Channel is one of the available Gypframe channels, especially designed to be used with the ShaftWall System, a lightweight system which can be installed in the early construction phase, especially applicable to areas wit..

£340.07

£408.08 inc VAT

Brand: British Gypsum

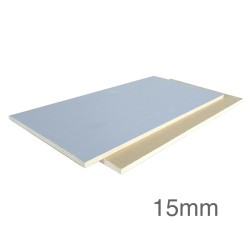

Model and Size: 1200x3000mm - 3.6m2

Delivery Time: 1 - 2 days

15mm Gyproc SoundBloc consists of an aerated gypsum core with glass fibre, water repellent and other additives encased in, and firmly bonded to strong paper liners--blue face paper, brown reverse side paper. This board is specially designed for use in heavy use areas where greater levels of sound in..

Guide Price: £28.75

£34.50 inc VAT

Related Products

Brand: British Gypsum

Model and Size: SIF5 - 55mm

Delivery Time: 3 - 5 days

55mm British Gypsum GypFloor SIF5 Floor Screws is used to fix floorboards through Gyproc Plank into the Gypframe SIF channel to prevent impact sound t..