Isocheck Acoustic Cradle (pack of 250).

- Product Code: A1-1047

- Delivery Time: 3 - 4 days

- Brand: Isomass (Tech. support: 08458383389)

- Model and Size: Cradle - 43mm - Free Delivery

4.6 out of 5 - Excellent

Isocheck Acoustic Cradle (pack of 250).

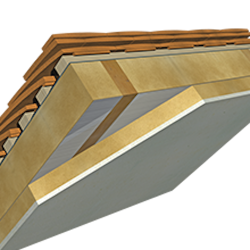

Isocheck Acoustic Cradle is a timber batten support system and a levelling system for uneven concrete floors, designed for reducing sound transmission and improving acoustic performance of uneven concrete floors. The system is used in new build refurbishment and conversion applications, including the possibility of combining it with underfloor heating systems, able to meet the requirements of the Building Regulations, Approved Document E 2003 (including the subsequent amendments in 2004 and 2010) and the Code for Sustainable Homes. The product is also in compliance with the New Build Robust Detail for masonry floors, where irregular concrete floor needs levelling.

CHARACTERISTICS

- Great acoustic properties;

- Especially designed for uneven concrete floors;

- Able to meet values prescribed by the Approved Document E of the Building Regulations, when installed as part of a complete sound reduction system;

- Can comply with Code for Sustainable Homes;

- Robust Detail compliant.

APPLICATION

Isocheck Acoustic Cradle is applicable in new build, refurbishment and conversion over cambered, uneven, unlevel and level concrete floors.

INSTALLATION

Prior to installation of the system, the following considerations must be taken into account:

- the building must be dried and weatherproof;

- any component of the flooring that is subject to wet conditions must be properly replaced;

- service location must be planned in the early phase of construction;

- all components of the system must be kept and stored in dry conditions.

The installation should begin in corridor areas and proceed to the rooms. Cambers and other low areas can be overcome with the use of elevating blocks and packers, which are a part of the system. Each cradle must be positioned on a flat, level spot. The support battens should be laid around the perimeter of the room, at around 50mm from the walls. The cradle needs to be installed so that it supports both meeting ends of the support battens. If the accommodating services need to run under the support battens, a deeper resilient cradle support must be specified, since the standard 11mm one will not allow this. The packers should be positioned within the shoulders of the cradle plate, whereas gluing is not usually necessary. At least 6mm expansion gap between the flooring edges and the perimeter walls should be maintained.

The floor panels should be laid across support battens. Flooring panel is fixed to the battens using annular ring nails and a suitable adhesive. The adhesive should be used to glue all grooved (on bottom) and tongued (on top) joints, in order of tightly butting all joints. Finally, the boards are fixed to the battens using at least four fixings across face of each batten.

CERTIFICATION

The product is in compliance with:

- Approved Document E of the Building Regulations;

- It can comply with Code for Sustainable Homes;

- New Build Robust Detail descriptive FFT2, typically within Robust Details E-FC-1, E-FS-1, E-FC-2 and E-FC-7.