Fire Barriers

Fire barriers are critical components in building construction designed to prevent the spread of fire and smoke through cavities in walls, floors, and ceilings. They provide essential protection by maintaining compartmentation and enhancing the overall fire safety of a structure.

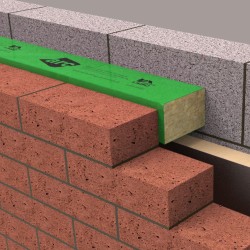

The widely used fire barrier material is rock wool (also known as mineral wool). Rock wool fire barriers are made from non-combustible, inorganic fibres derived from volcanic rock or basalt. This material is highly effective at resisting fire due to its excellent thermal insulation properties and high melting point, typically above 1000°C. Rock wool barriers are commonly used to fill cavities and gaps in walls and floors, providing both fire resistance and sound insulation. They are moisture-resistant, dimensionally stable, and do not promote mould growth, making them a reliable and durable choice for fire protection in a variety of building applications.

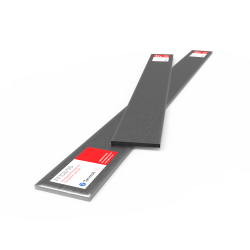

Another type of fire barrier is made from a low smoke, zero halogen, high expansion intumescent material covered with aluminium foil. This barrier is intended for horizontal installation within uninsulated, ventilated, and drained cavities up to 50mm wide. It is lightweight, easy to install, and requires no maintenance after fitting.

Key Features

- Rock Wool (Mineral Wool) Fire Barrier

- Made from non-combustible, inorganic volcanic rock fibres.

- High melting point (typically above 1000°C) providing excellent fire resistance.

- Provides thermal insulation and sound insulation.

- Moisture-resistant and dimensionally stable.

- Does not promote mould growth.

- Commonly used to fill cavities and gaps in walls and floors.

- Durable and reliable for long-term fire protection.

- Intumescent Ventilated Cavity Fire Barrier

- Made from low smoke, zero halogen, high expansion intumescent material with aluminium foil covering.

- Designed for horizontal installation in uninsulated, ventilated, and drained cavities up to 50mm wide.

- Lightweight and easy to install.

- Requires no maintenance after installation.

- Allows maximum ventilation and drainage, reducing the need for cavity trays or weep holes.

- Fire resistance rating of up to 120 minutes.

- Durable under various environmental conditions including UV exposure, rain, and frost.

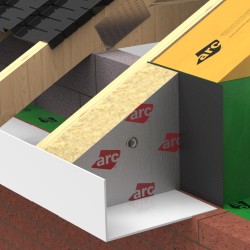

Typical Applications

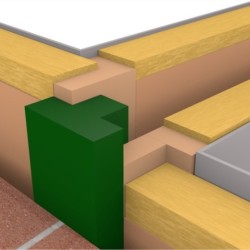

- Fire-stopping in wall cavities, floor voids, and ceiling spaces.

- Sealing around pipes, ducts, and cable penetrations.

- Compartmentalisation in commercial, industrial, and residential buildings.

- Enhancing fire safety in HVAC systems and electrical installations.