Types of External Wall Insulation (EWI) Systems

Types of External Wall Insulation (EWI) Systems

Choosing the type of building method and preferred materials for the external side of your external wall construction is dependent on a wide range of factors. Let’s unravel some of that mystery.

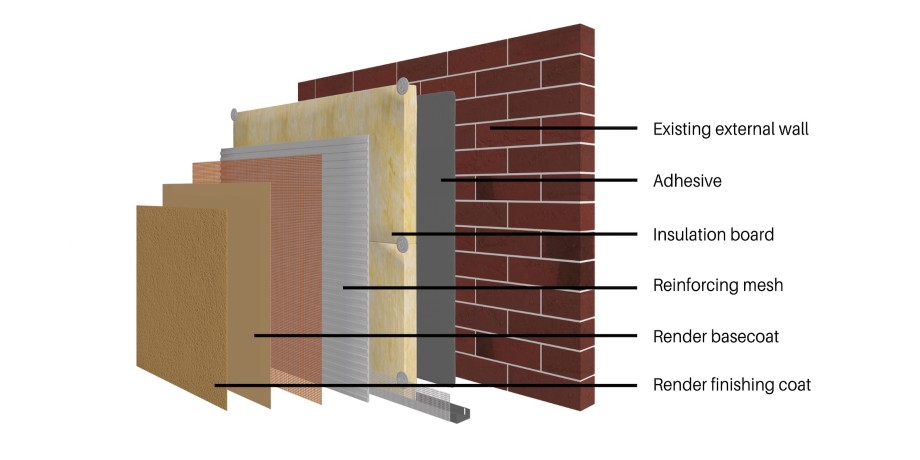

Basically, external wall insulation (EWI) systems involve insulation being placed on the outside of the core building structure with a protective face applied as the finished surface.

Different insulation types vary dependent on what the desired function and performance needs to be met. Deciding factors may include the required thermal performance, fire resistance, moisture resistance and/or sustainability issues.

There are two main types of construction methods: ventilated (vented or rainscreen) and unventilated (sealed) wall systems.

These are when insulation is fixed directly to the external side of the main wall structure. The insulation is placed on the exterior side of what is termed as the ‘core’ construction layer, for example: masonry (blocks, brick, concrete), timber or metal frame wall studs with external board and breather membrane applied before the insulation and external finish are added in front.

The final finish that is applied over the insulation can be render (Insulated or Thermal Render System) or alternates such as thin slip facings (brick or stone - usually around 10mm thick). The outer finishes form the weather barrier protecting the wall within.

Render finishes comprise of six types that offer varying aesthetic and performance characteristics. These include:

- Silicone renders

- Acrylic renders

- Silicate renders

- Silicate-silicone mixes

- Mineral renders

- Mosaic with resin finishes

Brick or stone slips: offer a lightweight alternative with these materials requiring suitable fixings designed to tie them securely through the insulation layer behind and into the main core construction layer.

Types of insulation that can be used include:

- Mineral wool (Rockwool brand is one example), which is a non combustible material offering a high level of non combustibility with good acoustic performance.

- Phenolic insulation boards: such as Kingspan Kooltherm K5, offers superior thermal efficiency with a thermal conductivity as low as 0.021 W/mK which allows for thin wall constructions. It has a high closed-cell content that makes it highly resistant to moisture and water vapour penetration compared to PIR boards. It is generally more expensive and has a greater environmental impact due to its raw materials and manufacturing process. The boards are suitable for use behind traditional and lightweight polymer modified renders and can be retrofitted externally to existing properties.

- Polystyrene;

- EPS (Expanded polystyrene insulation) boards: are a less costly option but offers a lower fire resistance.

- XPS (Extruded polystyrene board): has a higher moisture resistance with a high compressive strength, making it ideal for use below DPC level or in areas with a high moisture content.

- Wood-based insulations: ex: wood fibre boards or wood fibre insulation slabs boards; which are more “natural” materials that are often more permeable, making them better for breathability. They may have limitations depending on climate, moisture and fire code requirements.

There are many reasons and situations in deciding to use one insulation type over the other.

Mineral wool: is composed of volcanic rock which makes it a completely non-combustible product. Rockwool brand has achieved a Euroclass rating of A1, can withstand temperatures of up to 100 degrees C, prevent the spread of fires and not emit toxic emissions. It has an acoustic and dual density composition and is ‘breathable’ thus moisture trapped inside the existing wall can find its way to escape through the insulation, provided breathable finishes and materials are used on the external side of the insulation.

K5 Kingspan Kooltherm: has a rigid phenolic foam core, faced with a glass tissue board. It has an excellent thermal performance for a narrow structure. Its high compressive strength minimises any risk of mechanical compression and impact. Phenolic has a distinct pink colour, which is distinguishable from yellow PIR foam.

EPS: is the most popular insulation of choice. It has a low budget cost for its thermal efficiency class. It is a lightweight material designed to be placed onto masonry or timber backed walls using adhesive and mechanical fixings.

XPS: is a high density board that can be used for various building uses such as below DPC level insulation, extending concrete window cills or used as insulation backing boards where EPS is not suitable. It is compact and robust which makes XPS easy to store and reduces the risk of water penetration. Because of its closed-cell structure, excellent moisture resistance and high compressive strength it makes it a preferred choice for below DPC insulation.

In some situations, a breather membrane is placed behind the insulation, which protects moisture from entering into the structure but allows any moisture within the core structure to escape outwards thus reducing damp issues.

Ventilated External Wall Insulation systems (Ventilated Facades):

Ventilated Façade systems consist of a ventilated cavity between the insulation and the finished external or rainscreen cladding. There is a gap forming an air space (cavity) between the two that requires open ventilation gaps or slots along its length at the top and the bottom of the wall. In the UK, the CWCT (Centre for Window & Cladding Technology) recommend an air space cavity of minimum 50mm but individual manufacture products might suggest alternate measures such Equitone panels which recommend an air space cavity of minimum 30mm.

Unlike unvented systems, the exterior finish does not provide the weatherproofing to the wall. The outer finish’s functionality is to protect the wall build-up behind.

The purpose of the ventilation air space enables moisture within the building structure, to escape thus reducing condensation within the wall. This method allows the use of some types of cladding material options that have less moisture tolerances.

Breather membrane is crucial to be wrapped around the building envelope as it prevents rainwater from entering the building and has a double functionality of allowing any moisture within the building structure to escape through to the exterior. The location of the breather membrane is usually placed on top of exterior side backing boards or on the exterior side of the insulation but with some wall systems and insulation types, the insulation may be placed in front of the breather membrane.

The ventilated facade consists of four elements:

- Facade cladding

- Ventilation gap

- Rainscreen Insulation and breather membrane

- Substructure

Exterior rainscreen finishes/ claddings types include:

- Facade / architectural panels (such as fibre cement, wall systems from Rockpanel or Equitone, etc.)

- Weatherboards — wood, fibre-cement (such as from Cedral), plastic/composite boards etc.

- Ceramic or porcelain panels

- Natural stone, stone panels, terracotta tiles, slate tiles

- Metal panels or sheets (aluminium, steel, zinc, etc.)

- Face bricks (stone or brick slips)

- Precast concrete panels

- Rendered Fibre-cement boards such as Knauf Exterior Aquapanel boards

- Glass panels

Finishes can also be more traditional in construction such as bricks, masonry blocks and concrete which are porous, meaning moisture can make its way through this type of material. These materials need a construction type that is fully breathable that allows the moisture to escape. Ventilated facades allow for the water to be drained in the air space (cavity) behind and allows any humidity to evaporate. So if a wall type is not constructed as fully breathable through all of its materials, then a ventilated air space is required to allow the moisture to escape.

Equitone wall systems recommend that the breather membrane is installed behind the insulation. One reason for this is that the chosen membrane might be combustible. Equitone tests their systems with Rockwool insulation that type of insulation performs far superior than PIR insulation for combustibility.

To note, Victorian walls were built to be fully breathable with lime mortar and render finishes and lime paints. Modern construction materials, generally using concrete and chemical paints that require a ventilated air space unless a full-fill option is considered and is feasible for your situation.

Rainscreen cladding are structural panels that are fixed across the air (cavity) space to a backing supporting substructure.

The cladding primarily provides protection against wind, rain and sun. The longevity of the facade depends on their resistance to changing weather conditions and their inherent durability.

Ensure care is given to minimise thermal bridging of the support fixings to help maintain the thermal conductivity of the materials,

Vented systems are composed of the exterior finish whose functionality can be seen as more decorative but it screens the wall behind.

If there are gaps, of any size, in the finished panels that allow sunlight through, and if the breather membrane is exposed within the air space than a specific type of breather membrane that has resistance to UV (ultra violet) rays is crucial to use. Remember, that the breather membrane acts as the weather barrier to this type of wall construction.

If “Open Joints” are desired Equitone suggests that joints can be overlapped, covered or baffled. Generally a minimum joint size varies between 8mm to 12mm with the optimum joint width being 10mm.

Finished boards can be laid in multiple ways and patterns depending on the desired aesthetic effect. For example: horizontal, vertical or with angled lines. Boards can be of any shape and size. Options are dependent solely on your imagination and the manufacturers guidelines.

Of importance is the backing wall to the performance of a ventilated facade wall system. If air movement through the membrane is too high then the risk of water penetration is increased. Air leakage through the backing wall can create a means for energy/ thermal loss and so this must be limited in the design.

In multiple story buildings and large houses, horizontal fire protection stops might be required to prevent fire spread within the ventilated cavity between floors. These fire stops are usually made with an intumescent type of expanding material so as to expand in the case of a fire and seal off the cavity. These fire stops are installed at floor levels, and additionally above or below window and door openings. Building Regulations requirements vary from region to region, ie: England, Scotland and Wales, it is best to discuss your project with the local authority.

Insulation types commonly used in Ventilated EWI Systems include products from Rockwool and phenolic insulation boards. Refer to our range of insulation products:

https://www.insulationshop.co/cladding_and_weatherboard/insulation-for-ventilated-cladding.html

Here are some of the trade-offs and factors that help deciding between different EWI systems:

| Factor | Unvented (Insulated Render / Slips) | Vented / Rainscreen |

| Moisture & condensation risk | If well detailed, moisture risk manageable; but risk of trapped moisture behind renders or if render is impermeable. | The ventilated cavity helps remove moisture, allowing use of cladding materials less sensitive to moisture; better for durability in wetter climates. |

| Fire performance | Some insulation types (polystyrene) have lower fire classifications; renders/slips must meet relevant standards. | Cladding plus insulation plus cavity must all together satisfy fire codes; non-combustible insulation (rock wool, etc.) often preferred. |

| Thickness / U-value in limited space | Renders plus phenolic or high performance boards can get U-values with less thickness. | The need for cavity and support might increase build-out; but benefit is in flexibility of outer finish and maintenance. |

| Aesthetics | Render types offer large variety of finishes; slips provide masonry appearance. | Rainscreen gives options: panels, boards, natural materials; more architectural possibilities. |

| Cost | Render systems often cheaper in materials but labour cost for render finishing can be high; slip finishes more expensive. | More expensive cladding systems, framing, fixings; but possibly lower maintenance over time. |

| Maintenance | Render can crack, fade, need repainting etc; slips need mortar/fixings; renders must be repaired. | Claddings may need cleaning, occasional repair; but many rainscreen materials are durable. |

Stephan Silver

Xobo Design