British Gypsum GypCeiling Lining System

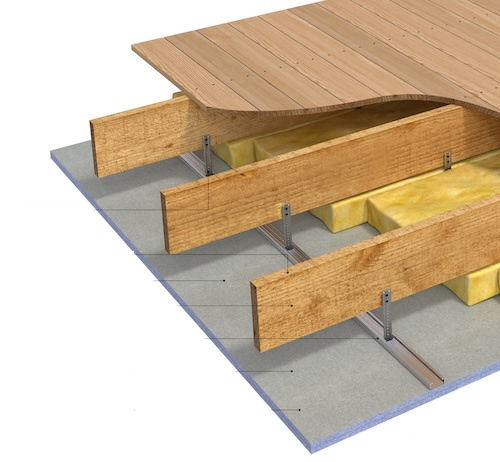

The GypCeiling Lining system is designed for directly fixing a metal frame to an existing structural soffit (like a concrete slab or timber joists) without a deep void, primarily for scenarios where a minimal drop or a slightly suspended performance lining is needed. It is particularly valued in refurbishment projects as it often requires less access than a full MF ceiling system. The GypCeiling Lining system is a high-performance, non-loadbearing drylining solution used to line the underside of a structural floor or roof. It creates a small cavity (a stand-off, typically ranging from 25mm to 175mm, depending on the bracket used) to accommodate minor services and deliver specific fire, acoustic, or thermal performance enhancements without the significant depth required by a full MF suspended ceiling.

The final result is a seamless plasterboard finish, which is jointed or skim-plastered. This system is often employed in residential refurbishments or commercial areas where ceiling height is critical.

Essential Gypframe GL System Components

The metalwork for this system is designated under the Gypframe GL series, reflecting its application as a direct lining rather than a deep furring system.

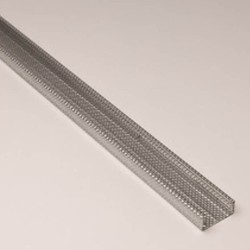

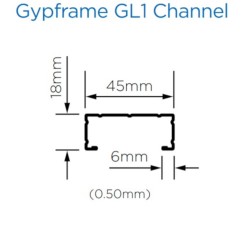

- Lining Channel: Gypframe GL1 - The primary metal channel. These are fixed directly to the structural soffit using specialised brackets and the plasterboards are screwed to the underside of these channels.

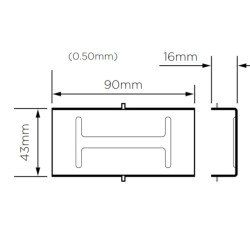

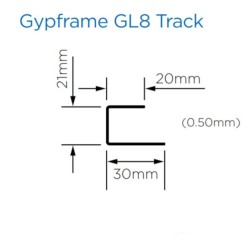

- Perimeter Track: Gypframe GL8 - A U-shaped channel fixed to the surrounding walls. It holds the ends of the GL1 Lining Channels around the room's edge.

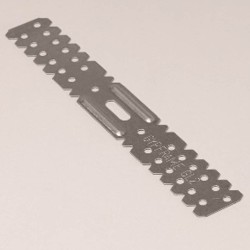

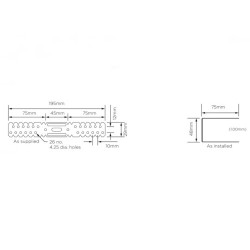

- Brackets: Gypframe GL2 / GL9 / GL12 - Suspension Brackets that secure the GL1 channels to the structural ceiling (e.g., concrete soffit). Different lengths (GL2, GL9, GL12) allow for variation in the size of the cavity created.

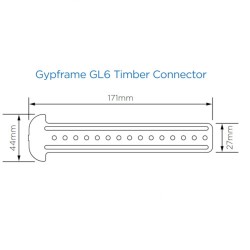

- Timber Connector: Gypframe GL6 - Used specifically when fixing the system to timber joists, rather than concrete, ensuring secure installation.

- Channel Connector: Gypframe GL3 - Used to join two GL1 Lining Channels together when a longer run is required.

Installation and Finish

- Framework: The GL8 track is fixed to the perimeter walls, and the GL1 channels are secured to the structural soffit using the appropriate GL brackets or GL6 connectors.

- Cavity: The brackets hold the GL1 channels down, creating a void (plenum) for running thin services like electrical cables or installing sound/thermal insulation (e.g., Isover Spacesaver).

- Lining: The chosen Gyproc plasterboards are fixed using specialised Drywall Screws to the underside of the GL1 channels.

- Finishing: The joints are typically finished using Gyproc Jointing Materials and tape, followed by decoration, or the entire surface may be finished with a skim coat of Thistle Plaster.

The performance of the GypCeiling Lining system is largely determined by the type of Gyproc board used to clad the metal framework.