9mm Renderflex Polymer Render Carrier Board

Guide Price

9mm Renderflex Polymer Render Carrier Board

Guide Price: £73.38 (£88.06 inc VAT)

Price per m2: £25.48/m2 (£30.58 inc VAT)

5 or more £71.65 (£85.98 inc VAT)

10 or more £70.47 (£84.56 inc VAT)

20 or more £68.66 (£82.39 inc VAT)

- Product Code: A1-1284

- Delivery Time: 3 - 5 days

- Brand: RCM (Tech. support: 01782940917)

- Model: 2400x1200mm - 2.88m2

- Weight: 35.71kg

Our ratings on 22-01-2026:

4.8 out of 5

9mm Renderflex Polymer Render Carrier Board

Thickness: 9mm

Width: 1200mm

Length: 2400mm

Board Coverage: 2.88m2

Density: 1378kg/m3

Weight/m2: 12.4kg

Weight: 35.71kg

Thermal Conductivity: 0.470W/mK

Fire Rating (Reaction to Fire): A2(Limited combustibility)

Sound performance: 28dB

Durability: 30 years

Surface: Front face – Smooth, Back face – Textured

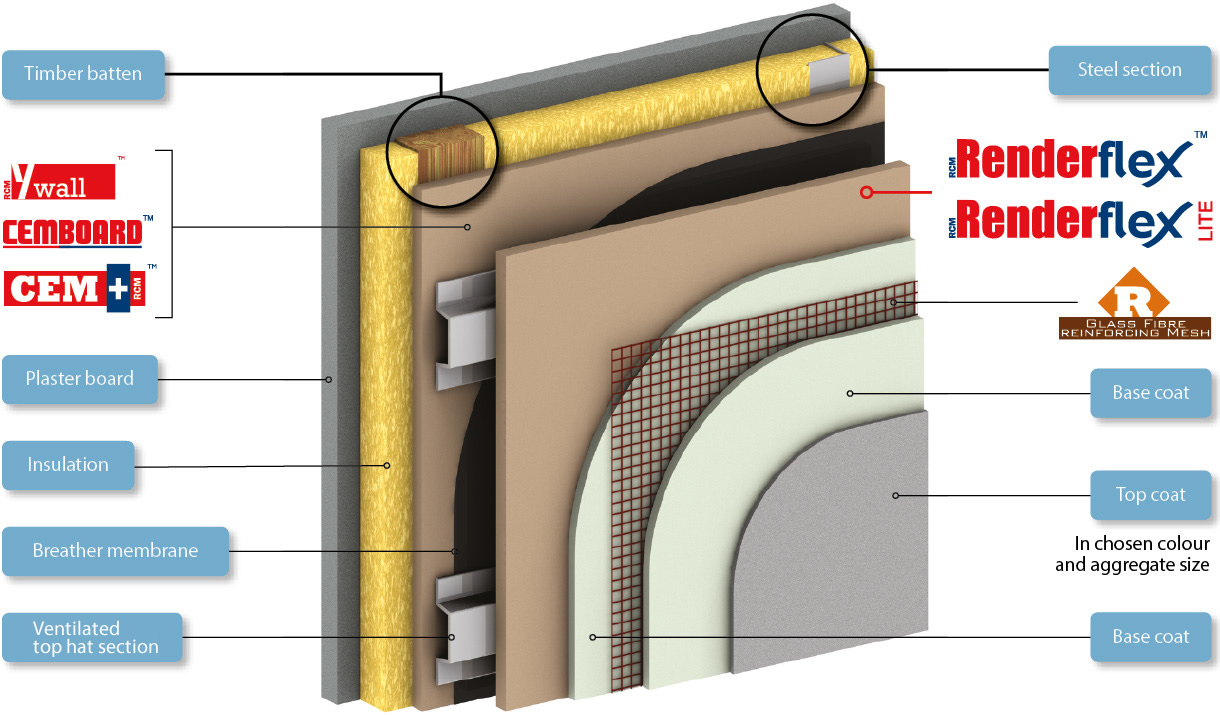

9mm Renderflex is a cellulose/fibre cement based render carrier board, primarily used as base board for polymer modified render systems which do not include insulation added to the board before rendering. It is made from a mixture of cellulose fibres, sand, Portland cement and some additives, offering substantial tensile strength thus providing durability and minimal movement in the board thus reducing stress applied to the render system. Classified as Class 0 in accordance with the BS 476 Part 6 & 7. The board is basically maintenance free which also makes it cost-effective.

APPLICATION

Renderflex is primarily used as render carrier board polymer modified render systems and internal and external wall linings.

CHARACTERISTICS

- Maintenance-free and cost-effective,

- Resistant to humidity changes and moisture,

- Vermin, insects and rot resistant,

- High tensile strength,

- Highly durable,

- High dimensional stability,

- Impact resistant,

- Easy to cut, drill and install.

INSTALLATION

- Renderflex board should be stored on a flat, smooth surface and in dry conditions.

- Make sure not to lay the boards upright or on edge.

- The boards should be carried on long edges and not dragged off the stack.

- The fixing of the board shall depend on type of fixings used, wind loading and applied loading, but the fixing pattern should generally be based in 600mm centres.

- The distance between the fixings and the board edge should be at least 12mm and 50mm in from corners of the board.

CERTIFICATION

- Conforms to EN12467;

- Associated with the NBS Create clause: 45-45-50/355 Fibre reinforced cement board.

Brand: RCM

Model: 3m length

Delivery Time: 1-3 working days

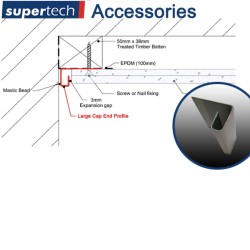

Supertech Aluminium End Profile 65 is a vital accessory designed to aid in the installation of Supertech planks for cladding projects. This finishing profile used where the end batten needs to be covered to provide a neat finish. Available in convenient 3-metre lengths, End Profile 65 trims are util..

Brand: RCM

Model: 2400x1200mm - 2.88m2

Delivery Time: 1 - 2 days

18mm RCM Cemboard is a medium density high performance cement bonded particle building board used primarily as an external sheathing or acoustic building board on both metal and timber frame structures. This rigid Cemboard offers great strength and stability with the workability of wood. RCM Cemboar..

Brand: RCM

Model: 3m length

Delivery Time: 1-3 working days

Supertech Aluminium External Corner Bay Profile is essential accessory designed to facilitate the installation of Supertech planks in cladding projects. This profile used to provide a neat finish to the external corners of a bay window. Available in 3-metre lengths, it ensures a perfect fit for your..

Brand: RCM

Model: 2400x1200mm - 2.88m2

Delivery Time: 3 - 5 days

6mm RCM Y-Wall is a fire rated high performance calcium silicate cement building board used primarily as an external sheathing board on both metal and timber frame structures. This rigid RCM Y-WALL board offers great strength and stability with the workability of wood. It can be cut, drilled and nai..

Brand: RCM

Model: 2400x1200mm - 2.88m2

Delivery Time: 3 - 5 days

15mm RCM Y-Wall is a fire rated high performance calcium silicate cement building board used primarily as an external sheathing board on both metal and timber frame structures. This rigid RCM Y-WALL board offers great strength and stability with the workability of wood. It can be cut, drilled and na..

Guide Price: £66.99

£80.39 inc VAT

Brand: RCM

Model: 2400x1200mm - 2.88m2

Delivery Time: 1 - 2 days

12mm RCM Cemboard is a medium density high performance cement bonded particle building board used primarily as an external sheathing or acoustic building board on both metal and timber frame structures. This rigid Cemboard offers great strength and stability with the workability of wood. RCM Cemboar..

Guide Price: £60.25

£72.30 inc VAT