Kingspan Kooltherm K5 Insulation Board for External Wall Insulation Systems

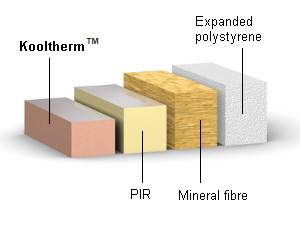

We are well aware that the insulation market has expanded over the years, now offering a variety of insulation products that can be used either independently or as part of innovative insulation systems. However, this variety can make it challenging to make the final and, more importantly, the right choice. Since wall insulation is extremely important today due to the numerous potential benefits it can provide—including significant cost savings, improved energy efficiency, environmental protection, enhanced stability and soundness of the wall, and an overall upgrade in thermal performance—we will reveal everything you need to know about Kingspan Kooltherm K5 insulation board and its application in external wall insulation systems.

Kingspan Kooltherm K5 external wall insulation board is a highly efficient rigid phenolic insulation board, consisting of a premium performance rigid resin insulant, covered with glass tissue-based facings on both sides, which are bonded to the insulation core during the manufacturing process. The insulation core of the boards is produced with zero Ozone Depletion Potential (ODP) and low Global Warming Potential (GWP), making the board extremely environmentally friendly. The boards are available in standard dimensions of 1200mm x 600mm and various thicknesses ranging from 20 to 80mm.

What also makes these boards an excellent choice is their great comprehensive strength, water resistance, and the fact that they essentially do not have an expiration date if properly installed (the durability will also depend on the stability and characteristics of the surrounding and supporting structure). The key to their durability lies in their resistance to microbial growth, vermin, and mould. Although the core of the boards is resistant to most mineral oils and alkalis, it is advised that any spills should be properly removed and cleaned according to the provided instructions prior to installation. Kingspan K5 insulation boards are also suitable for commercial and industrial applications, as they offer a level of fire resistance and are Class 0 fire rated in accordance with applicable regulations.

How to install

Kingspan K5 phenolic insulation wall board has wide application in insulating cavity walls and solid walls and is usually used as a part of insulated render systems. Prior to commencing the installation, the following considerations should be taken into account:

- The boards can be cut using either a fine-tooth saw or by applying the score and snap technique with a sharp knife and a straight edge.

- All edges of the boards should be properly trimmed to ensure continuous insulation.

- If the installation work cannot be completed in a single day or experiences any extended interruptions, all board joints and edges should be adequately covered and protected from the weather.

- The boards are designed for indoor storage; however, if they must be stored outside, they should be covered with appropriate weatherproof sheeting.

- The boards are safe to use and do not require any special equipment or installation conditions.

Insulated render systems

Please note that the installation of Kooltherm K5 insulation boards will depend on the render system used. However, the following general rules may also apply:

- The boards should be installed onto a clean and smooth surface, so ensure that all dirt and protrusions are removed. If necessary, use a bedding compound to address any remaining uneven surfaces before fixing the boards.

- The boards should be fixed at 150mm below the top surface of the ground insulation for a concrete floor and 200mm below the top surface of the ground insulation for a suspended timber floor. The installation should be carried out in a brick-bond pattern, and all board joints should be tightly butted. Special care should be taken around all reveals concerning the insulation thickness.

- The boards are fixed to the external wall using appropriate fasteners, with a minimum of five fixings per board, located at a minimum of 300mm centres at external corners and openings, and more than 50mm but less than 150mm from edges and corners (please refer to the render system manufacturer to determine whether additional fixings are required).

- Once the Kingspan K5 wall boards have been installed, take care to avoid cold bridging when reattaching ancillaries and services, and use sill extenders and flashings around openings in refurbishment projects. Finally, check with the render manufacturer to see if glass fibre mesh or bedding mortar needs to be applied.

For any additional information contact us through our live chat support system or send us an email to info@insulationshop.co.