Filling Service Voids with Rockwool Ablative Coated Batts

Making your building envelope fireproof has become very useful (and obligatory) not only for heavy industrial buildings, but also residential properties, all in accordance with the Building regulation, Part B concerning fire safety in dwellings. Namely, when considering fire protection and resistance, there is a bit more to it than just choosing the best fire proof material, especially if you are considering adding insulation to the entire structure, both as a separate layer or through a building material that already has some insulation characteristics incorporated. Things get complicated when you have to run all the necessary services through the building structure (such as pipes, ductwork or electric cables), since these can create a gap in the structure and thus interrupt the continuous line of fireproof materials. Well, these gaps and service voids need to be somehow filled in with a proper material that will follow the fire proof properties of the entire structure. In order of making your life easier, we shall herewith consider the question of filling service voids with Rockwool Ablative Coated Batts.

Fireproof Elements and Materials

When providing proper protection for your floors and walls, including creating fireproof service voids, you must consider at least three important aspects of every construction work:

- moisture resistance and

- fire resistance.

All these issues need to be addressed in the early construction phase, in order of avoiding serious problems later on. This means that every construction element (especially walls and floors) needs to be covered with some insulation material, which, depending on the specific requirements of each space, needs to have adequate moisture and fire resistant characteristics. Please note that there aren’t general rules applicable on fire performance of each element, but this will depend on many factors, including the desired results and applicable regulation. However, it is good to know that certain materials are more efficient when it comes to fire performance than others and should thus be chosen whenever there is greater risk of fire breaking out. When speaking of fire resistance, you will notice that this can be looked at (and tested) in two different ways – as the ability of a material in question to resist fire and to prevent the flame and fire from spreading, when it already breaks out, whereas both aspects are equally important. For example, rigid PIR and PUR insulation products will not allow the flame spread since the material will harden once it burns out, which is not the case with polystyrene boards which will allow flame and smoke spread. Thus, our advice is to look for insulation products that possess a certain level of fire resistance, such as specially designed products, including Knauf Fireline Plasterboard which is developed to offer superior fire resistance performance when used in partition, ceiling and lining systems or Promat Monolux Fire Protection Boards, designed to maintain stable strength and rigidity when exposed to maximum temperatures of 500°C.

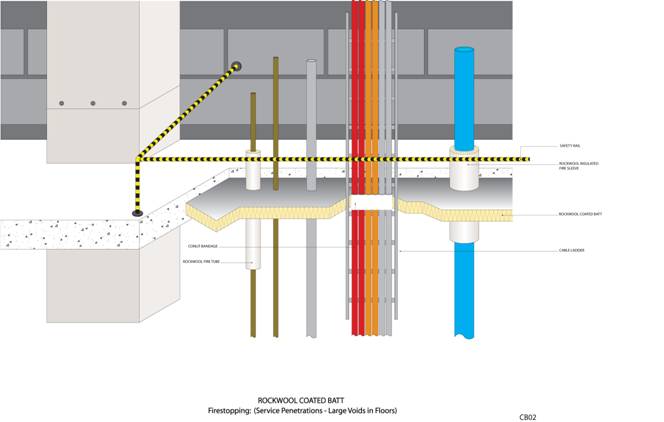

Rockwool Ablative Coated Batts ReviewNow that we have considered some basics on fire proof materials and fire resistance, it is time to move on to some more detailed work which includes the best way to ensure fire resistance of structural service voids. As before mentioned, these voids created by service penetrations (such as pipes, ductwork or cables) need to be properly sealed and what better than some material that has desired fire resistance characteristics, such as rock wool which, depending on the thickness and manufacturing process, Euroclass A1 classified (non combustible) and it will not combust when exposed to fire nor will it spread flames over the construction.

Namely, if you have read the previous few lines on fire resistance carefully, you have come to understand that, in order of creating a fire proof structure, you need a material that will seal the potential voids that however, also needs to be fire proof. This is why our advice goes for Rockwool Ablative Coated Batts which are manufactured from rock wool and coated on both sides with special ablative coat, for up to four hours of fire resistance for a single batt. Please note that the fire performance can be upgraded by using a few layers of the batts, if the structure allows you to. Apart from fire resistance, the batts also provide great level of soundproofing, which is particularly important for residential properties, but also prevent smoke spread and improve air tightness of the entire construction. They are very easy to install, since they are very lightweight, allowing them to be tightly fitted between the service voids and the wall or floor edges. Apart from sealing voids of up to 20m in length and 1.2m in height, the batts can also be used for blank seals of up to 2880mm x 2400mm dry walls or masonry walls, or up to 600mm x 600mm in concrete floors. Rockwool Ablative Coated Batts can be used for drywall systems, masonry walls and concrete floors, and can be combined with a wide range of different materials, including steel, cast iron, copper, polypropylene, high density polythene etc. For all those of you that are concerned about its ecological effects, it would be good to share the fact that the batts are completely eco-friendly, since 97% recyclable, having 0 ODP and GWP potential.

You can now order rockwool ablative coated batts right here at Insulation Shop, at affordable prices and big discounts. Send your quote enquiries to info@insulationshop.co or order directly from our insulation online shop.