Speedline MF Ceiling System

The Speedline MF Ceiling System is a robust and fully certified metal frame solution designed to create a completely flat and seamless suspended ceiling, ready to receive a final decorative finish, such as plastering (skimming) or jointing. It is a preferred system in commercial offices, residential developments, healthcare, and education sectors across the UK due to its reliable performance and compliance with British and European standards.

The Speedline MF System version is used to:

- Conceal Services: Create a plenum void beneath the structural slab or roof, allowing all unsightly services (ducting, cables, pipework) to be hidden from view while remaining accessible.

- Enhance Performance: Deliver improved fire resistance and sound insulation (acoustic separation) between floors, achieved through the combination of the metal framework, the cavity depth, insulation, and the choice of plasterboard lining.

- Provide a Seamless Finish: Offer a higher-quality aesthetic than visible-grid tile ceilings, resulting in a smooth, monolithic surface suitable for high-specification areas.

- Flexibility: The depth of the void is entirely variable, and the system can accommodate complex design features like bulkheads and changes in ceiling height.

Key Speedline MF System Components

Speedline's MF components are typically manufactured from galvanised steel and are referenced using a straightforward numbering system similar to other major UK manufacturers.

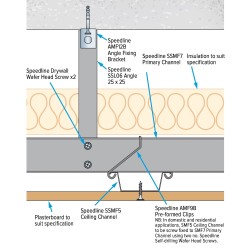

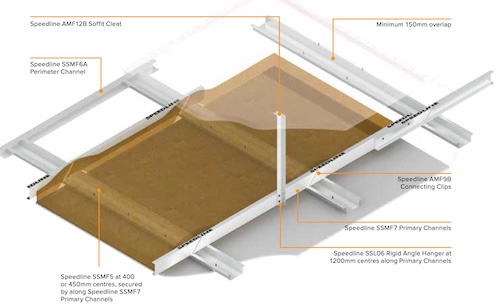

- Primary Channel: SSMF7 - The main load-bearing channel. These run in one direction and are suspended from the structural soffit using hangers. They support the entire ceiling weight.

- Ceiling Channel / Furring Section: SSMF5 - Often referred to as a 'Top Hat' section due to its shape. These secondary sections run perpendicular to the SSMF7s and form the grid to which the plasterboard sheets are fixed.

- Perimeter Channel / Edge Trim: SSMF6A - An angle section fixed to the perimeter walls, providing support for the ends of the SSMF5 Ceiling Channels where they terminate at the wall.

- Rigid Angle Hanger: SSL06 - A rigid steel angle (e.g., 25×25 mm) used as a hanger to suspend the SSMF7 Primary Channels from the structure above, sometimes secured with an AMF12B Soffit Cleat.

- Connecting Clips: AMF9B - Pre-formed metal clips used to mechanically join the SSMF5 Ceiling Channels to the underside of the SSMF7 Primary Channels, creating the interconnected grid.

- Acoustic Hangers: AAH01B / AAH02B - Optional resilient components used instead of rigid hangers. These de-couple the metal framework from the structural soffit, significantly enhancing the airborne and impact sound insulation performance of the system.

Lining and Finishing

- Once the Speedline framework is erected, it is lined with standard plasterboard or specialist boards (like FireLine or SoundBloc, often from Siniat, British Gypsum, or Knauf) fixed using Drywall Screws at recommended centres (e.g., 230 mm in the field and 150 mm at the edges).

- The final surface is then completed using either taping and jointing to fill the seams or by applying a thin coat of plaster skim, giving the ceiling its final seamless appearance.

CHOOSE MANUFACTURERS

Brand: Speedline

Model: SSMF5 - 50mm - 3600mm

Delivery Time: 2 - 3 working days

50mm Speedline Metal Furring Ceiling Channel is a cold-rolled, galvanised steel section, commonly used as a heavy-duty Primary Channel within a suspended ceiling or wall lining structure. Its key characteristic is its depth of 50mm, which provides exceptional rigidity and strength over longer spans ..

Brand: Speedline

Model: AAH01B - 35mm - Box of 100

Delivery Time: 2 - 3 working days

35mm Speedline AAH01B Acoustic Hanger is a specialised anti-vibration component designed for use with the Metal Furring (MF) Ceiling System. Its entire purpose is to prevent sound energy (particularly impact noise and vibration) from transferring directly from the structural floor/ceiling above into..

Brand: Speedline

Model: AMF12B - Box of 1000

Delivery Time: 2 - 3 working days

Speedline AMF12B Angle Fixing Bracket (often referred to simply as a Soffit Cleat) is a small but heavy-duty accessory that forms the crucial interface between the structural ceiling (the soffit) and the suspended metal framework of the MF system. The AMF12B is a compact, robust bracket, typically t..

Brand: Speedline

Model: AMF9B - Box of 200

Delivery Time: 2 - 3 working days

Speedline AMF9B Pre-formed Clip is an essential connecting accessory used to construct the two-way grid framework of the Speedline MF (Metal Furring) Ceiling System. This clip provides the mechanical connection between the two main channels, the SSMF7 and the SSMF5. The AMF9B is a small, engineered ..

Brand: Speedline

Model: SSL06 - 3000mm

Delivery Time: 2 - 3 working days

The Speedline SSL06 Rigid Angle is a versatile L-shaped steel section primarily designed to function as a Rigid Angle Hanger within the Speedline MF (Metal Furring) Ceiling System. It is the component responsible for suspending the main load-bearing channel (the SSMF7 Primary Channel) from the struc..

Brand: Speedline

Model: SSMF6A - 3600mm

Delivery Time: 2 - 3 working days

The Speedline SSMF6A Perimeter Channel is a specialist profile metal section used to establish the boundary and seating for a suspended metal furring (MF) ceiling system. It is a critical component that interacts directly with the wall structure. The SSMF6A is described as a U-shaped steel section w..

Brand: Speedline

Model: SSMF7 - 3600mm

Delivery Time: 2 - 3 working days

The Speedline SSMF7 Primary Channel is the most critical structural part, as it is responsible for supporting the entire weight of the ceiling grid and the plasterboard lining. The SSMF7 is a deep, sturdy channel, typically featuring a broad, flat base and two vertical legs, often described as an in..

Showing 1 to 7 of 7 (1 Pages)