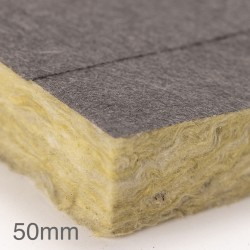

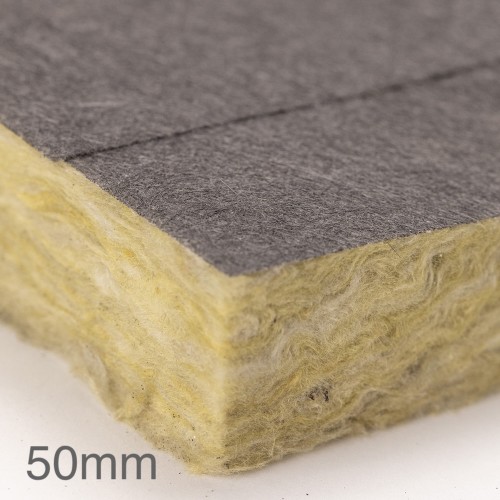

50mm Siderise Black Tissue Faced Stone Wool Acoustic Lining Slab - 1200mm x 1000mm

- Product Code: A1-6313

- Delivery Time: 5 - 7 days

- Brand: Siderise (Tech. support: 01473827695)

- Model: 1200mm x 1000mm - 1.2m2

- Weight: 4.74kg

50mm Siderise Black Tissue Faced Stone Wool Acoustic Lining Slab - 1200mm x 1000mm

50mm Siderise Black Tissue Faced Stone Wool Acoustic Lining Slab is a non-combustible insulation solution to deliver outstanding acoustic absorption and thermal performance. This product is ideal for exposed applications where both effective sound control and a neat, aesthetically pleasing finish are required. Manufactured from resilient, high-density stone wool (rock mineral wool), the slab boasts an exceptional open-fibre structure that efficiently absorbs airborne sound, significantly reducing reverberation and echo within various spaces. Its inherent non-combustibility ensures it contributes to passive protection, providing a robust and safe acoustic solution. Its factory-applied, black glass tissue facing serves multiple purposes: it prevents fibre migration, offers enhanced visual appeal for exposed installations (such as in plant rooms, studios, or open-plan offices), and provides a clean, finished surface. The black facing helps to blend the insulation discreetly into darker environments or provides a consistent aesthetic for exposed ductwork and ceilings. Siderise Black Tissue Faced Stone Wool Acoustic Lining Slab is easy to cut and handle, allowing for straightforward installation. It is commonly specified for lining internal walls, ceilings, ductwork, plenums, machinery enclosures, and other areas where superior acoustic performance, thermal insulation, and a refined appearance are paramount.

CHARACTERISTICS

- High-density, resin-bonded stone wool (also known as rock mineral wool or rockfibre).

- Factory-applied black non-woven glass tissue (or fabric) facing on one side.

- This facing prevents fibre shedding/migration.

- Provides a clean, aesthetically pleasing finish for exposed applications.

- Ensures consistent sound absorption properties.

- The facing helps prevent fibre shedding, contributing to better indoor air quality.

- Absorbs airborne sound, reducing reverberation and echo.

- Achieves Euroclass A2-s1,d0 (EN13501-1).

- Comply with UK Building Regulations Approved Document B.

- Provides thermal insulation.

- Resilient, dimensionally stable, and designed for long-term performance (often stated to last the lifetime of the building).

- Easy to cut to size and handle, allowing for straightforward installation using standard techniques (e.g., insulation hangers).

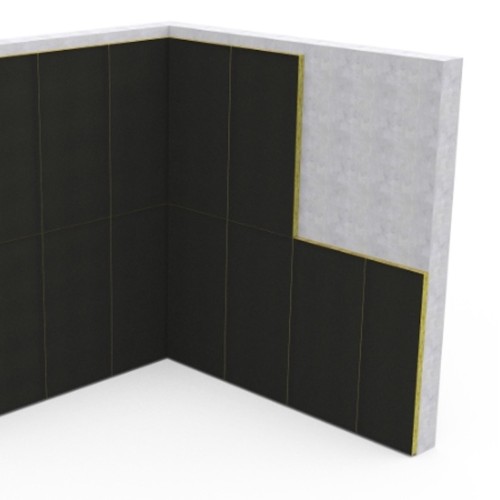

APPLICATION

- Ideal for cinemas, auditoriums, studios, plant rooms, soffits, HVAC ductwork lining, internal wall linings, ceilings, acoustic enclosures, and other acoustically-sensitive areas or exposed applications.

INSTALLATION

- Ensure the substrate is clean, dry, and structurally sound to support the insulation.

- Use a sharp, long-bladed knife or a saw designed for insulation to cut the stone wool slabs to the required size and shape.

- The black tissue face should be cut cleanly to maintain its integrity.

- Using Siderise Self-Adhesive Perforated Insulation Pins, once the pins are securely adhered, impale the stone wool slab onto the pins, ensuring the black tissue face is on the exposed side.

- Then, secure the slab by pressing a self-locking washer onto each pin. Trim or bend over any excess pin length.

- Where slabs meet, ensure butt joints are tight to maintain acoustic and thermal integrity.

- Carefully cut the slabs to fit snugly around any penetrations (pipes, ducts, electrical conduits).

- Seal any significant gaps with an appropriate fire-rated acoustic sealant if required by fire stopping regulations.

- Clean up any loose fibres or dust generated during cutting.