12.5mm Euroform Easyboard - Exterior Grade Fibre Cement Board - 800mm x 1200mm

- Product Code: A1-6328

- Delivery Time: 2 - 3 working days

- Brand: Euroform (Tech. support: 01925860999)

- Model: 2400mm x 800mm - 0.96m2

- Weight: 10.80kg

12.5mm Euroform Easyboard - Exterior Grade Fibre Cement Board - 800mm x 1200mm

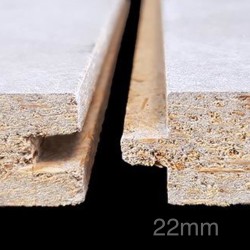

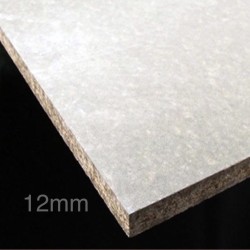

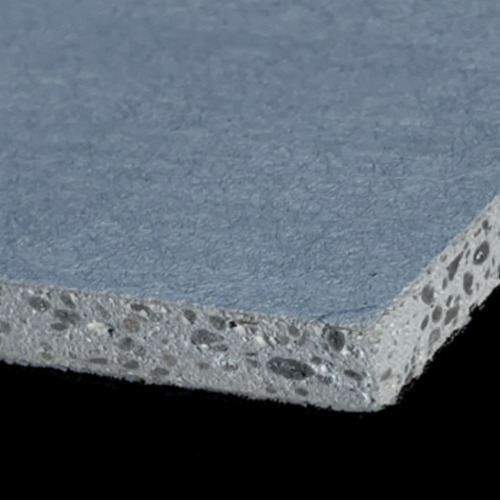

12.5mm Euroform Easyboard a high-performance exterior-grade fibre cement board, engineered to combine the inherent durability of Ordinary Portland Cement (OPC) with ease of installation. It serves as a versatile and robust solution for both external sheathing applications and internal tile backing in moisture-prone areas. Easyboard features a unique composition that includes mesh reinforcing facings, enhancing its workability and handling properties. It has a highly convenient 'score & snap' capability, allowing for swift and clean cutting with a standard utility knife, significantly reducing installation time and on-site dust compared to conventional power tool methods. With an A1 non-combustible fire rating (to BS EN 13501-1), Easyboard provides superior fire safety performance, making it suitable for use in fire-critical areas. It offers exceptional dimensional stability, being inorganic and highly resistant to moisture, making it an ideal substrate for tiling in kitchens, bathrooms, and other high-humidity environments. Its inherent durability ensures a minimum life expectancy of 50 years.

APPLICATION

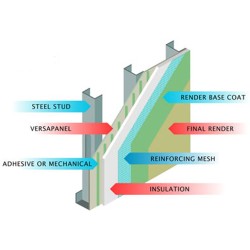

- Ideal as an exterior sheathing board for steel frame system (SFS) walling.

- Suitable as a render carrier board for direct render applications (e.g., in External Wall Insulation systems).

- Excellent tile backing board for high-moisture areas like kitchens, bathrooms, and wet rooms (walls and floors).

CHARACTERISTICS

- Exterior-grade fibre cement board, combining Ordinary Portland Cement (OPC) with a reinforcing matrix and mesh facings.

- A1 Non-Combustible (to BS EN 13501-1), providing superior fire safety.

- Can be scored and snapped.

- Highly dimensionally stable (low expansion/contraction with humidity changes).

- High resistance to moisture, rot, and vermin.

- Minimum life expectancy of 50 years.

- Enhanced workability and handling properties compared to traditional fibre cement boards.

- Relatively lightweight for a cement board, aiding single-person installation.

- Smooth greyish surface, uncoated as delivered.

INSTALLATION

- The supporting framework (timber or steel studs) should be true, level, and securely fixed. Ensure it can adequately support the board and any subsequent finishes (tiles, render).

- Breather Membrane (for external sheathing):

- A suitable breather membrane must be used behind Easyboard when it's applied as an external sheathing board.

- Easyboard itself does not prevent moisture ingress.

- Waterproofing (for wet areas/DPC level):

- Where boards are used below and within 150mm of the DPC (Damp Proof Course) level, a compatible waterproofing membrane should be applied.

- Compatible EPDM membranes should be used around other areas at risk of water ingress, such as window openings.

- Easyboard can be installed in either 'portrait' (vertical) or 'landscape' (horizontal) orientation.

- Easyboard is typically fixed using self-drilling screws (e.g., self-wing drilling screws) suitable for the substrate (timber or steel framing).

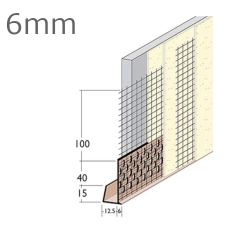

- The first fixing from any corner (horizontal and vertical) must be 40mm in from the edge.

- Fixings around the perimeter of the board should be at approximately 15mm from the edge.

- Spacing for intermediate fixings (within the body of the board) typically should not exceed 250mm (or as per project specific requirements, ensuring adequate support).

- Leave a minimum 3mm gap at all board joints. This allows for slight dimensional changes due to relative humidity.

- All board joints must be taped.

- External Sheathing:

- Once installed, Easyboard may be exposed for up to 12 months before being covered with a breather membrane and final facade system (e.g., render).

- Ensure proper detailing around openings (windows, doors) with compatible waterproofing membranes (e.g., EPDM).

- Internal Tiling (Walls & Floors):

- Easyboard should be primed prior to tiling with an alkaline-tolerant primer.

- Use a flexible adhesive (minimum Class C2 according to EN 12004-1) when placing tiles.

- Maximum tile weight for walls should not exceed 50 kg/m²; for floors, 100 kg/m².

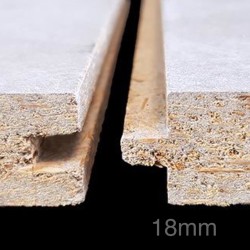

- When used as a floor tile substrate, ensure the Easyboard is fully supported by a true and flat structural flooring system (e.g., timber floorboards).

- Where used in wet rooms or areas directly exposed to water, a suitable tanking or waterproofing system must be applied over the Easyboard before tiling.

- Always refer to the latest Euroform Easyboard Technical Data Sheet and Installation Guide for detailed, application-specific instructions and any local building code requirements.

CERIFICATION

- Euroform Easyboard has obtained BDA Agrément certification.

- Fire Rating (Reaction to Fire): It achieves an A1 Non-Combustible rating in accordance with BS EN 13501-1.

- It is conformity assessed according to BS EN 12467:2012+A2:2018 “Fibre-cement flat sheets”, specifically classified as Category B, Class 1.

- It is UKCA marked.

- Euroform Products achieved assessment with the CCPI in the UK.